TSA 1200 traysealer

Up to 20 cycles/min in cut&seal and up to 15 cycles/min in MAP. Automatic traysealing machine for all kind of preformed regular trays. Can make modified atmosphere (MAP) and vacuum packing. Tray transport system with arms. Suitable machine for integration in process automation with high production performance.

Automatic tray sealer for all type of trays and materials. Different printed top film materials can be used. Depending on the requirements of the product to be packaged, MAP, vacuum, skin... can be made.

This equipment has been designed for integration into high production lines or processes with high accuracy in tray positioning.

They can work in single-line or double-line, according to the specifications of trays and model.

DESIGN HIGHLIGHTS

- Hygienic design.

- Sealing force.

- Easy cleaning.

- Robust construction.

- Easy to use.

- Reduced maintenance costs.

- Versatility.

- Energy efficiency.

- High production performance: up to 15 cycles/min.

- Easy change of format.

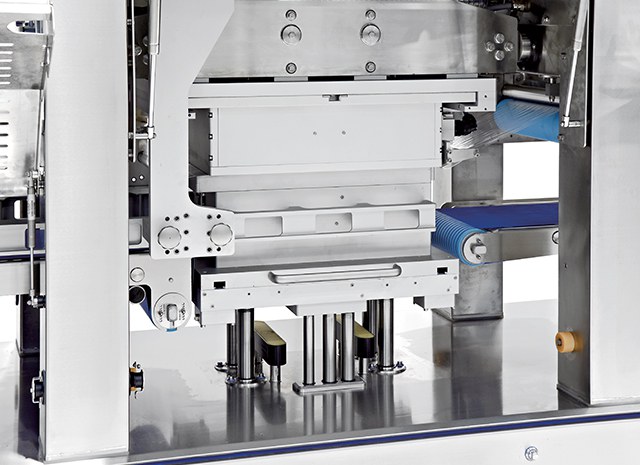

- Maximum sealing area: 330 x 1200 mm.

- Maximum tray height: 80/120 mm.

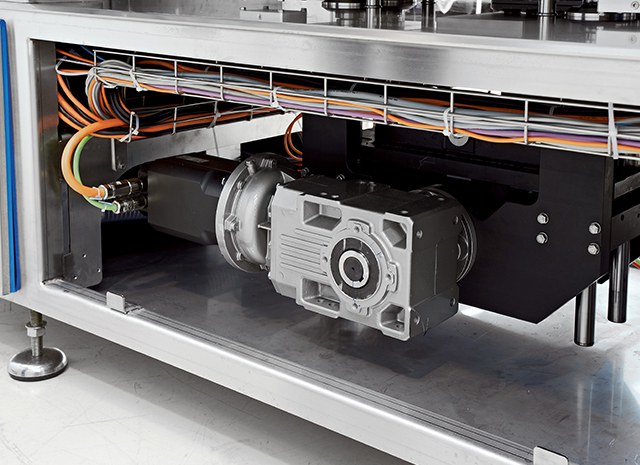

- Die lifting system by servomotor.

- Arm opening/closing and die transfer by servomotor.

- Die change: Quick and easy change without tools and die/dome positioning detectors.

- Protection rank: IP 65.

- Tray feeding and positioning by belt with drum-motor.

- Belt disassembly without tools.

- Gas pressure control by panel (recordable). Gas accumulator tank included.

- Reel holder: pneumatic grip.

- Film end and break detectors.

- Motorized film tension control.

- Centralized lubrication system.

- 10 "Panel Control (UPC-10B-C) with Industry Suite 4.0.:

- Assistant on screen (SOP).

- Customizable interface.

- Remote connectivity.

- Maintenance program: event management.

- Tray denester.

- Loading modules.

- Infeed conveyors.

- Dosing and product loading systems.

- Die holder trolley.

- Accumulator table.

- Tray convergers.

- Coding and printing systems.

- Seal tester.

- Metal detectors.

- Integration into end of lines.