OEE monitoring

To fully optimise productivity, it is essential to

have around-the-clock information about your

equipment's efficiency data (OEE)

OEE DATA ENTRY / OEE MONITOR

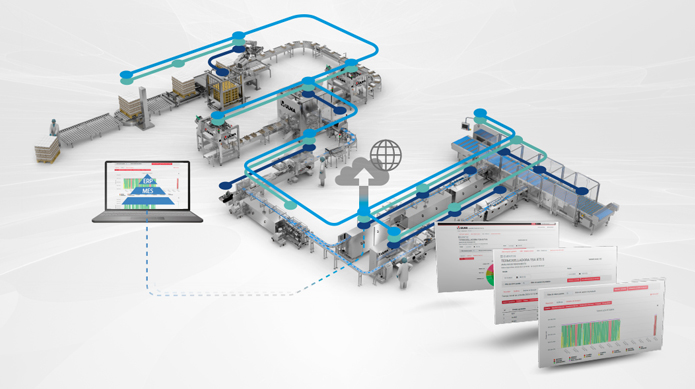

Our packaging machines include features that optimise the efficiency of production lines: their robustness, reliability, the ease with which they can be changed and adjusted, synchronisation of operations, inclusion of infeed systems with a continuous flow of the products to be packaged, etc.

To fully optimise productivity, it is essential to have around-the-clock information about your equipment's efficiency data (OEE). For this purpose, we have designed a set of software tools on our UPC 4.0 and Rockwell control platform, such as: OEE Data Entry and OEE Monitor.

OEE Data entry is an application that is available on our control panel (HMI) for collecting production information, either manually or automatically, through MES and ERP production

systems.

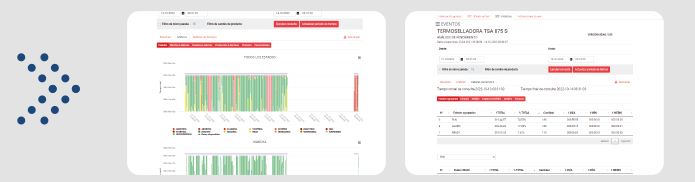

» Efficiency indicators by orders/shifts

» Measurement by units or lines

» Available with UPC 4.0 and Rockwell (with Xdevice) control systems

» Remote visualisation

» Analysis can be viewed on the panel and on the MyULMA customer portal

With OEE Monitor, the data is analysed and the Overall Equipment Efficiency (OEE) is automatically calculated, displaying a real-time report in numerical and graphical form in a user-friendly environment, enabling the immediate analysis of the data and its evolution. This facilitates downtime troubleshooting and the creation of specific improvement plans.

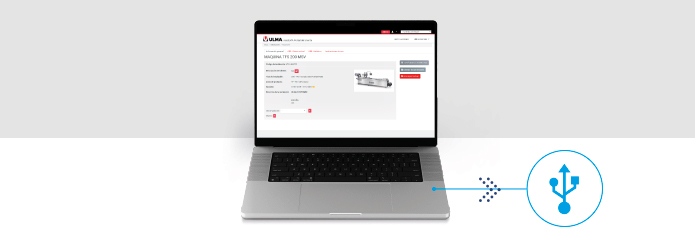

The OEE information is displayed both on the machine's control panel and in myULMA customer portal. It can be stored on an external device (USB) and can be available on MyULMA for up to 12 months, to allow performance trends in production operations to be compared over time.

![]()