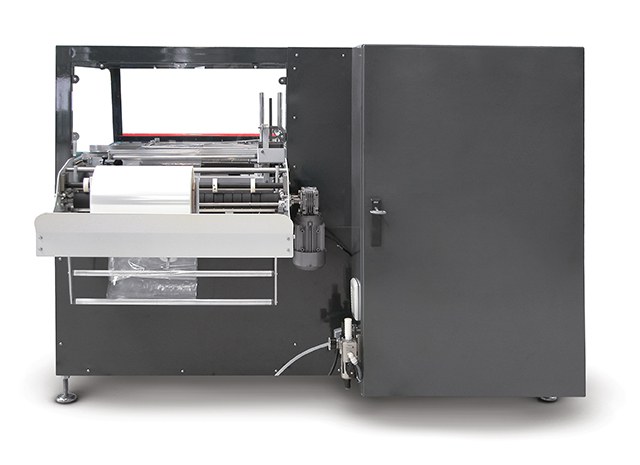

Side seal shrink machine SC 200

Automatic side seal machine for shrink films as well as not shrink films. Medium-high performance level.

The automatic SC side seal machines have been designed to pack all type of products whatever may be the length, with shrink and non shrink films, for productions of up to 85 cycles / min.

Versatile machine with simple regulations, it is quickly adaptable to the different products to be wrapped.

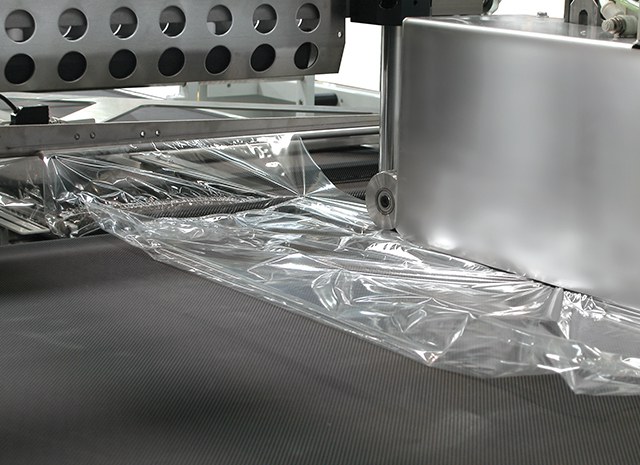

Side sealed packs avoid seals over and under, giving clear products with or without shrinking.

The SC 200 has been specially designed to achieve high productions, even with frequent format changes, including devices that allow for fast and easy changes without the need of tools.

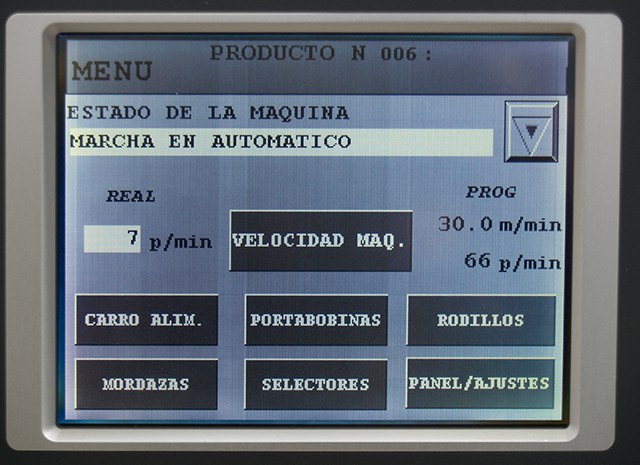

An industrial PC control system includes a simple and quick communication system through touch sensitive screen which provides constantly a complete diagnostics of the status machine and the control parameters.

- Automatic in-line feeding on a conveyor belt with product separation and alignment systems of the product and manual conveyor width regulation.

- Motorized 90º film reel holder placed at waist level, with adjustable mechanic perforation and film end detection. Easy loading of film.

- In feed manual moving belt makes easier to put and change the film.

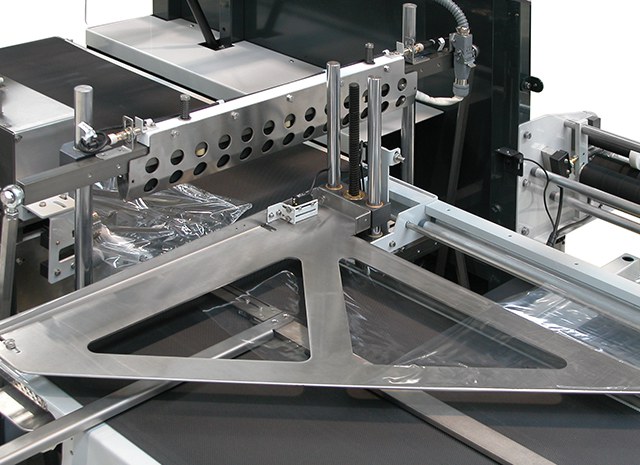

- Triangle frame height with motorized adjustment from the touch screen.

- Product detection photocells (horizontal and vertical).

- Cross seal and cut by hot knife with temperature regulation. Easy to replace.

- Side seal by warm wheels with temperature regulation.

- Side movement of the sealing head for high products (Opt. Mod. SC 200 / 500)

- Three opening pneumatic settings at the cross seal (Mod. SC 200 / 500) and with servo driven motor at any height. (Mod. SC 200S / 500S)

- Motorized adjustment of the cross seal opening and closing, from the screen, with sealing jaw safety system.

- Solid estate relay provide minimum temperature oscillations of the cross and side sealing systems.

Motorized adjustable height sealing head so that the seal is always central to the pack. (Opt. Mod. SC 200 / 500). - Kissing conveyor belts for wrapping small or instable packs. (Opt. Mod. SC 200 / 500).

- Automatic film scrap wheel with easy access. Film distribution device and film break detection.

- Control, functions and adjustments of parameters through PC industrial.

- Touch screen control panel easy to operate.

- Memory for up to 100 different formats of products.

- Heavy duty frame construction made from laminated and painted steel tube.

- Legs adjustable in height. Wheels for location and transport.

- Orientation of the machine: From right to left.

- Adaptable to existing production lines.

- Easy access to all elements.

- Ventilated electric cupboard.

- Operation diagnosis.

- Parameters and messages on screen.

- Protections and safety systems according to CE norms.

- Automatic pack format adjustment.

- Powered regulation of the in feed conveyor width.

- Cross sealing bar and side seal for PE.

- Split belt in feed for vertical pack detection of irregular and low products.

- Film folding system from flat to centerfold.

- Air blower for film opening.

- Independent speed of the side seal system and the out feed conveyor belt.

- Pneumatic hole punch.

- Hot film perforation.

- Film perforator for easy opening.

- Over head device.

- Extension of the in feed belt in 500 mm for wider products.

- Double film reel holder.

- End of film detector.

- Film centring device for printed film.

- Coding systems.

- Light (three colours) and sound alarm.

- Timer for automatic warm up and cool down.

- Machine direction: from left to right.

- Stainless steel version.

- Different feeding and exit elements (feeders, pushers, ramps, conveyors, etc)

- MODEM for diagnostic of failure.