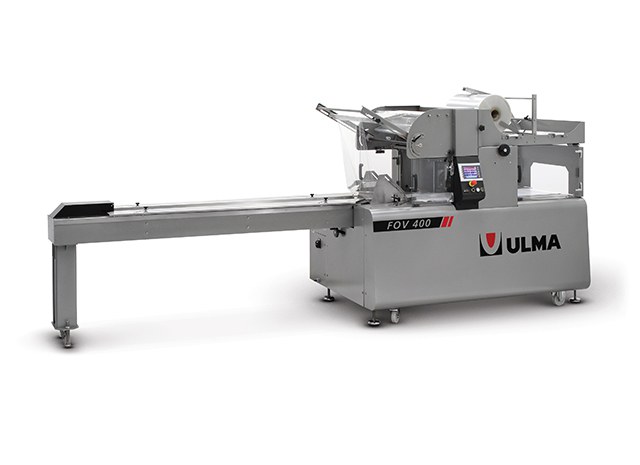

FOV 400 flow pack wrapper (HFFS)

Automatic wrapping machine developed to shrink-pack or to film-wrap a wide variety of products in a flow-pack (pillow pack) format creating an overlapped longitudinal seal.

FOV 400 is an automatic wrapping machine developed to shrink-pack or to film-wrap a wide variety of products in a flow-pack (pillow pack) format creating an overlapped longitudinal seal.

The FOV 400 machine is the result of the ULMA commitment with the innovation and the technological development of our products. The machine has been developed by a combined team made of specialized engineers and researchers in the ULMA Packaging Technological Center, and the result is a robust construction and a very high flexibility machine that incorporates the state of the art packaging technology.

This high flexibility on the FOV 400 machine, allows wrapping a wide variety of products by simple and fast change-overs, and also allows using different wrapping materials on the same machine. The robust construction of the machine is complemented with an Industrial PC based electronic control, and a touch screen that allows to control and store in a data base the settings for the different products to be wrapped.

- Electronic machine controlled by an Industrial PC based motion control system for an increased flexibility.

- The machine is built on a strong painted steel frame.

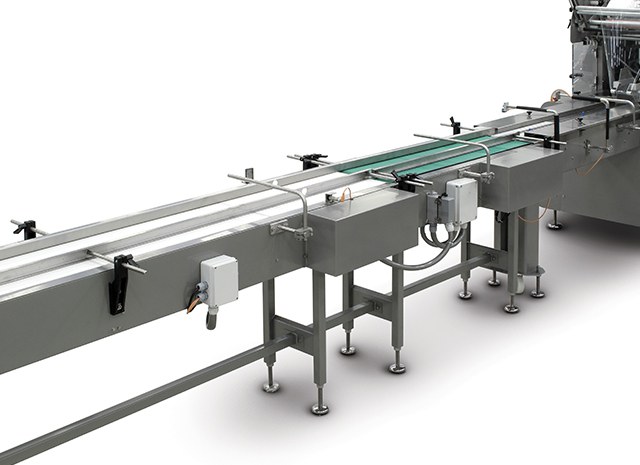

- The feeding conveyor is a pusher type in-feed that carries the product and synchronizes its position automatically with the cross sealing head.

- Equipped with a double reel holder for rolls up to 850 mm. wide and 350 mm. in diameter.

- The flexible forming box allows to adapt the film tube to the different products to be packed.

- The longitudinal overlap sealing system is created by an ionizer for shrink-wrap packs, or by means of a hot sealing system for film-wrapping packs.

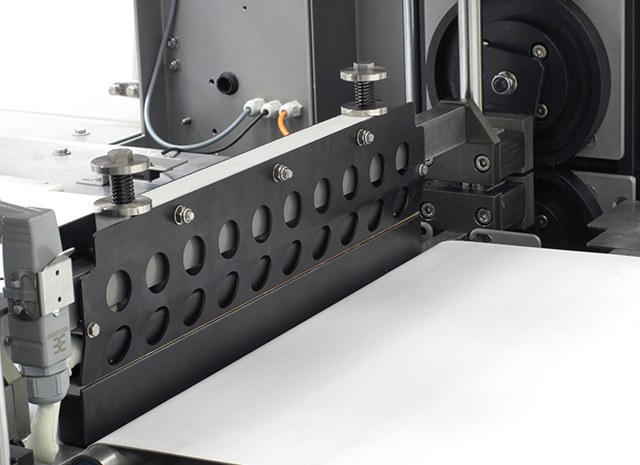

- The cross seal is created by a Long-Dwell sealing head system with sealing jaws that are 400 mm. wide. The system is powered by a brushless servomotor.

- The machine includes the "No product - no bag" function as standard. This function avoids creating empty bags while the in-feed conveyor keeps running in a continuous mode and hence optimizing the production.

- The control panel is equipped with a touch screen for the user/machine interface. The screen uses very intuitive menus in a user friendly environment which allows a quick setting and storage of the different parameters.

- Mixture version designed to run shrink polyolefin film and Low Density Polyethylene (LDPE) on the same machine, ideal for contract packers.

- Print registration photocell.

- Automatic feeding and indexing system for regular products.

- Wide variety of in-feed conveyor designs is available in variable lengths to accommodate the required lay-out.

- Wide variety of friction feeders, labelling equipment, printing equipment, ...