Wide range of automated tortilla packaging solutions

Automated packaging machine loading

The packaging machine product loading process can be automated thanks to our range of robot or retractable belt-based systems.

Primary thermoforming packaging

For anyone seeking to prolong their product's shelf life, primary thermoforming packaging is the right solution. With precise control of the residual oxygen in the packaging, it ensures that the product is kept in suitable conditions for 9 months for when it is consumed.

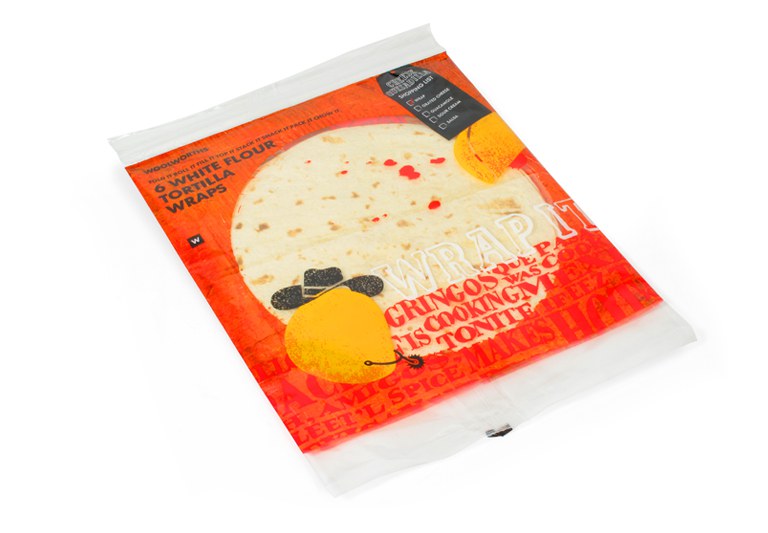

Primary flow wrappring packaging

For customers who want maximum format flexibility with optimal packaging costs, primary flow pack packaging provides a wide variety of options for resealable packs, making it the best choice.

TThe product's shelf life, which can be up to 2 months, can be increased by using oxygen absorbers, which are placed inside the packaging.

The ease with which packaging formats can be changed when using flow pack packaging machines minimises downtime, thus improving the line's OEE.

Our resealable packaging options include:

- Adhesive lengthwise or crosswise on the pack

- Zipper lengthwise or crosswise on the pack

Automated end of line solutions

Through our UPA process automation division, ULMA Packaging also provides end of line solutions that automate and reduce the costs associated with handling during the end of line phase.

- Pack aligners at the exit of the thermoformers

- Automatic rejection by robot or belt

- Packing robots that work on tracking

If you would like to see our packaging formats, go to our solutions for tortillas and wraps section or, if you would prefer to contact us directly, you can get in touch by using the form provided here.