ULMA Packaging, specialists in packaging and automation solutions

Thanks to the know-how we have acquired after more than 60 years of experience as a leading global supplier of packaging solutions for the main food and pharmaceutical sectors, we are able to offer our customers tailored automated solutions to meet the requirements of their packaging lines.

With over 1800 dedicated professionals across the world, we are at the forefront in the design of the best automation solutions.

Committed to innovation and sustainability, we strive to offer a global and local service that helps to optimise our customers' production efficiency and packaging quality.

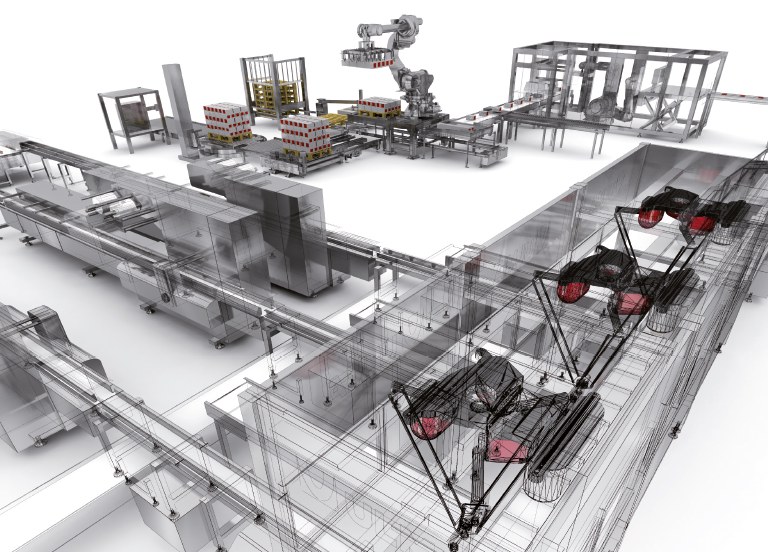

COMPLETE LINES AND TURNKEY SOLUTIONS

Our wide range of packaging machines and fully automated systems mean that we can offer our customers primary packaging machines and turnkey solutions that are tailored to their needs.

Our knowledge of advanced technologies and process control ensures high productivity rates with the best quality in terms of primary, secondary and tertiary packaging solutions. Whether we are designing a solution from scratch or integrating your primary packaging process into an automatic line, we make your packaging process as efficient and reliable as possible.

Designed, assembled, delivered and supported by our specialist engineers, we aim to be your single source, one-stop supplier.

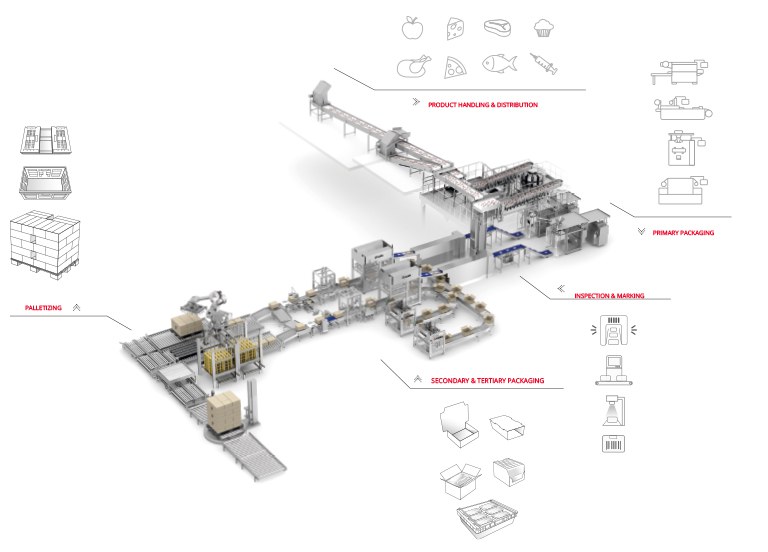

We automate the whole packaging process from product loading to final packaging and palletising.

- PRODUCT HANDLING, DISTRIBUTION AND FEEDING

- PRIMARY PACKAGING

- QUALITY CONTROL AND INSPECTION AND MARKING SYSTEMS

- SECONDARY AND TERTIARY PACKAGING SYSTEMS

- PALLETISING

ULMA PACKAGING, MORE THAN AN ENGINEERING COMPANY

At ULMA Packaging, we offer our customers a full project life cycle management service and after sales service.

We work to build long-term relationships with our customers that are based on trust, in order to help them meet the most stringent efficiency and reliability requirements with the shortest possible installation times.

Our value propositions include:

- SINGLE SOURCE SUPPLIER

As an experienced OEM, we are able to integrate both our own and third-party equipment in a single project in order to design a fully integrated line that provides outstanding performance and efficiency. - LINE TESTING

The complete line is fully tested before it is shipped, reducing the start-up curve and ensuring optimal machine efficiency (OEE). - LOW TOTAL COST OF OWNERSHIP (TCO)

As original equipment manufacturers, we optimise integration by using the smallest possible number of components, thus facilitating maintenance, which extends the machine's service life and reduces the cost of the project. - CUSTOMISED PROJECTS

Due to our extensive knowledge of packaging processes, and thanks to our vast experience in automation technologies, we tailor the design to each customer’s specific requirements. - DIGITAL SOLUTIONS

We supply Industry 4.0-ready machines, where connectivity, visualisation and automation are the key to simple and centralised operation of complete lines and seamless integration into plant processes.

HOW CAN WE HELP YOU?

If you are thinking of improving the efficiency of your packaging lines or are considering partially or fully automating your packaging lines, do not hesitate to contact our experts.