ULMA Packaging presents a new automatic packaging line for bars and baked goods with outputs of up to 200 packs/minute

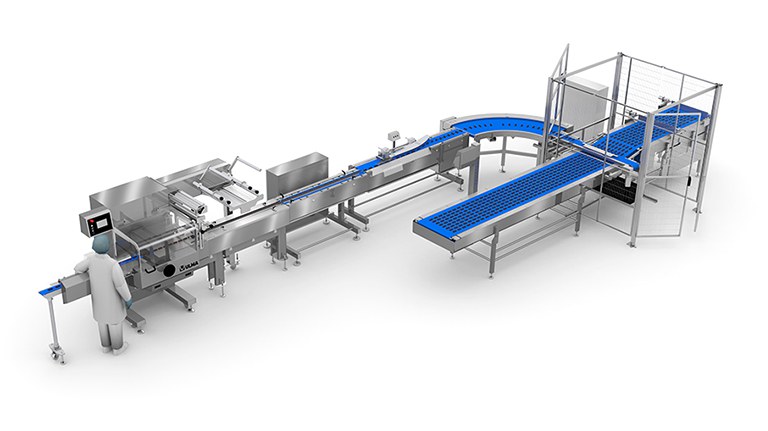

The line consists of a receiving conveyor on which the products are sorted and lined up for subsequent even and continuous distribution to one or more packaging machines. They are distributed on a swivel conveyor that places the rows of products on another, subsequent conveyor. The product can also be transferred to an accumulation conveyor or a reject conveyor if there is any defect.

The optional installation of an accumulation or buffer conveyor after the distributor significantly improves the line's OEE because, if there is an issue on the packaging line, the system transfers the remaining rows to that accumulation conveyor and they are then automatically transferred back to the wrapper when it detects a gap.

The FR 200 flow pack wrapper's feeder delivers the products to the packaging machine evenly.

This new multi-conveyor has been designed in this way to reduce its size and achieve a more compact line. It is also now even easier and simpler to change the belts, thus optimising maintenance and cleaning times.

This is a highly flexible and versatile line that is capable of working with a variety of product sizes. Controlled using an industrial PC, our UPC 4.0, which comes with advanced interconnected manufacturing features as standard, allows you to connect to the machine remotely, analyse and monitor OEE and view operating instructions and videos etc.

In line with ULMA Packaging's commitment to achieve the most sustainable packaging possible, this flow pack wrapper is equipped to work with easy-to-recycle sustainable film.

MAIN BENEFITS

- Small layout

- Highly flexible

- Equipped to use sustainable film

- Remote connection

- Product receiving conveyor

- RDS-DT 0 row distributor with swivel conveyor

- Product row removal conveyor at 90º

- Conveyor that fills gaps between products

This automatic line for medium-sizes batches joins the existing range of high-speed automatic packaging lines for bars and baked goods in our catalogue.

Do not hesitate to contact us if you are interested in finding out more about this or any other packaging system