ULMA Packaging expands its production capacity with a new plant specializing in Automation Solutions

With a surface area of 10,000 sqm and an investment of 12.5 million euros, this new facility is a response to the sustained growth of our business and the increasing demand from our customers for automated solutions that enhance the efficiency and profitability of their packaging processes.

To boost our production capacity and provide an even more efficient service to our customers, we have developed a plant equipped with the highest technological standards. This new infrastructure allows us not only to expand our range of automation solutions but also to optimize the integration of packaging systems before shipment.

Complete Lines and Comprehensive Solutions

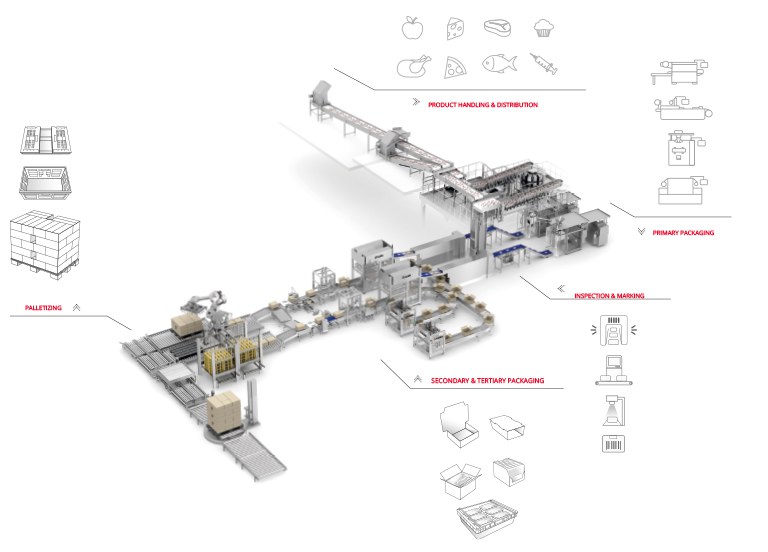

Our extensive range of packaging machines, combined with our fully automated systems, enables us to offer customers both primary packaging machines and comprehensive solutions tailored to their needs.

Our expertise in advanced technologies and process control ensures high productivity rates with the best quality in primary, secondary, and tertiary packaging solutions. Whether designing a solution from scratch or integrating your primary packaging process into an automated line, we make your packaging process as efficient and reliable as possible.

We work on automating the packaging process, from product loading into the packaging machine to palletizing:

- Product handling, distribution, and feeding

- Primary packaging

- Quality control, inspection, and marking systems

- Secondary and tertiary packaging

- Palletizing

Commitment to Customers and Sustainable Development

The opening of this new facility reflects our commitment to continuous improvement and sustainable growth. We have a highly qualified team dedicated to developing efficient solutions tailored to the specific needs of each customer, offering turnkey projects that optimize the performance of their facilities and provide a range of key benefits:

- Increased production capacity

- Greater efficiency of the packaging line (OEE)

- Improved production flow within plants

- Material savings and lower cost per package

- Reduced labor costs

- Lower maintenance and repair costs

With this step, we reinforce our position as strategic partners in the automation of packaging processes, ensuring advanced technological solutions that combine efficiency, sustainability, and a high level of customization.

How can we help you?

If you are considering improving the efficiency of your packaging lines or evaluating the partial or total automation of your packaging processes, do not hesitate to contact our experts.