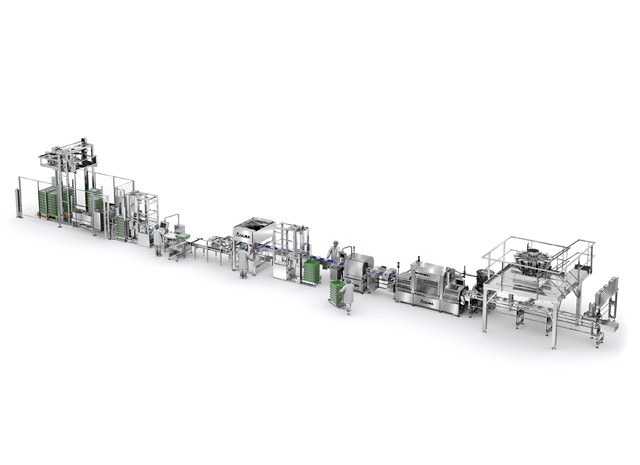

Complete line for packaging of ready meals

Complete line for traysealing packaging of convenience food and ready meals

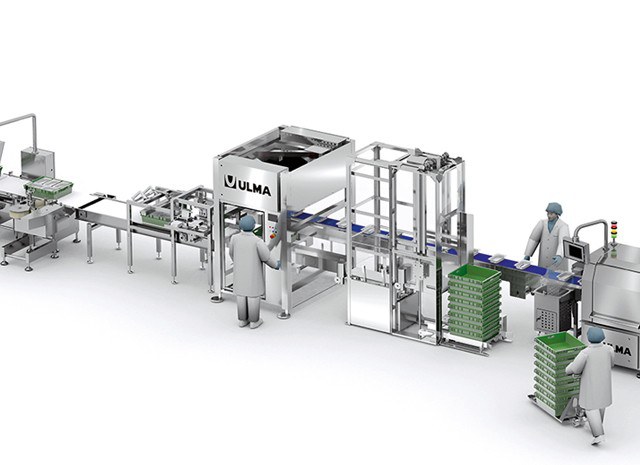

The line begins with a tray denester that has a stack of trays to feed the cadence required by the traysealer.

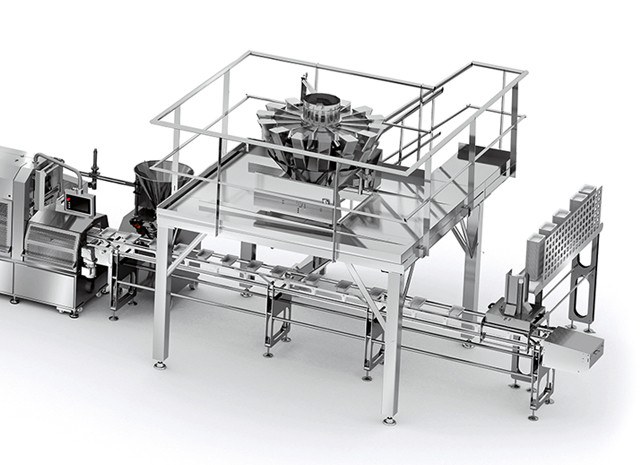

The multi-head weigher loads the product into the trays so that later a dosing system provides de sauce to the product in continuous motion.

The hygienic design traysealer works at high cadence sealing the trays with lid film.

Each traysealed package is inspected by several elements arranged in line. In the first place, by the metal detector and secondly by an artificial vision system that checks the sealing perimeter to detect possible leaks in wrong sealed trays.

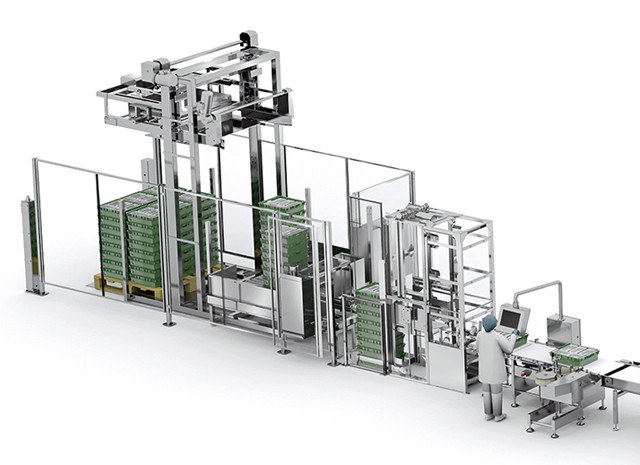

The plastic crate destacker removes the crates from the pile to supply the case packing cell.

The robotized case packing cell loads the plastic crates with the traysealed packages so that immediately and automatically the bar of the crate is closed in order to be stacked.

The stacker is responsible for making the piles of crates that are transported to the palletizer.

The mechanical palletizing realizes the pallets of crates so that packages are directed towards the area of finished product.