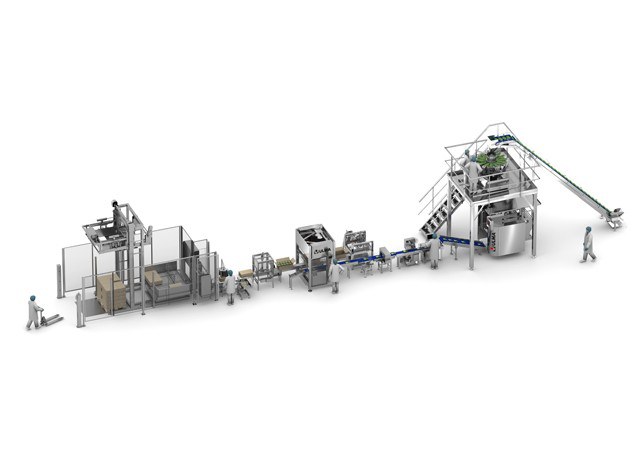

Complete solution for fresh cut vegetables and salads packaging in vertical bagger

Complete line for vertical packaging of fresh cut vegetables and salads.

The line begins with a lifting belt that transports the fresh cut vegetables to the multi-head weigher that is responsible for making the doses that each bag will contain.

The vertical wrapper makes bags with product according to the indicated weight. ULMA has systems specially designed to avoid production stops due to the difficulty of dragging this type of products.

After the bagging of the product, a labeling machine integrated in the line is in charge of labeling the bags so that immediately afterwards they pass through a metal contaminants inspection system that will reject those packages that do not comply with the specifications.

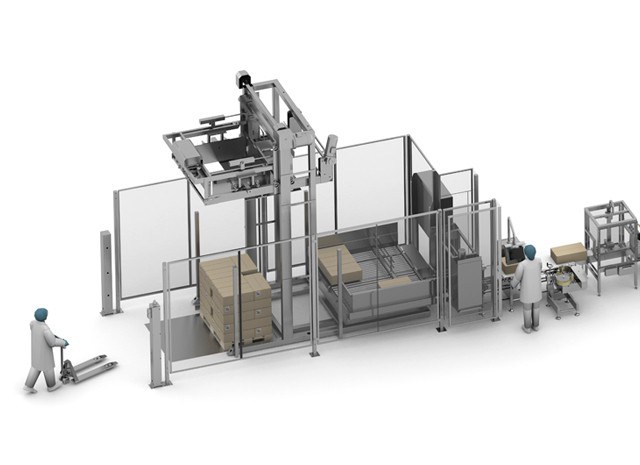

A case erector performs carton boxes from sheets. Both the boxes and the bags are transported to the automatic case packing cell. The robot case packs the bags into the carton boxes. Subsequently, an inline closing system closes the boxes for labeling and palletizing.

The mechanical palletizing system receives the carton boxes containing the product bags and prepares the pallets with the corresponding stacks so that an operator picks them up with a hand pallet truck.