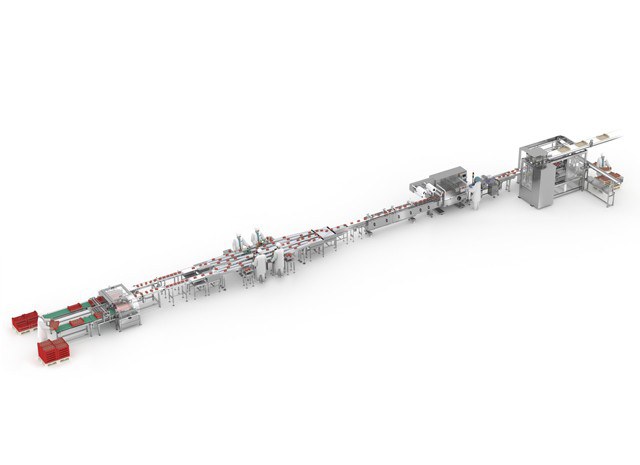

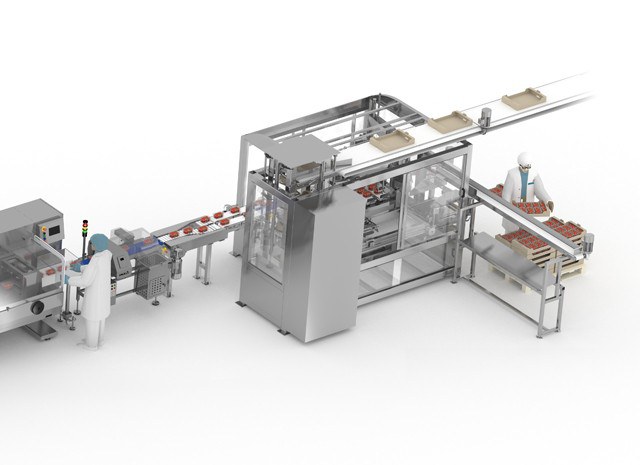

Complete solution for flow wrapping of strawberries in trays

Complete line for the packaging of strawberries trays in flow pack wrapper.

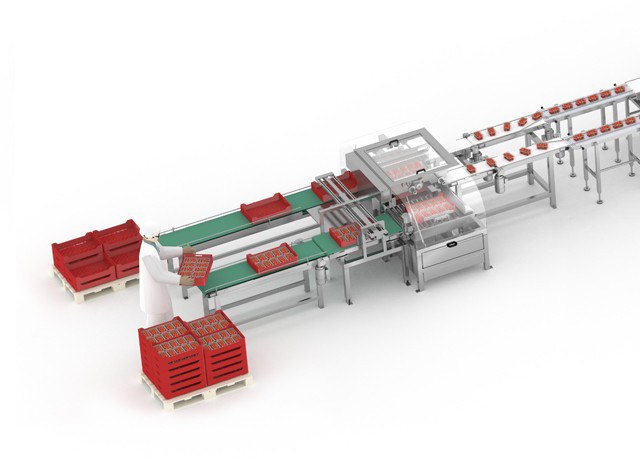

The strawberries come in plastic trays that are in a plastic crates. It is necessary to perform the corresponding unpacking in order to be able to weigh and wrap each tray in a primary pack.

The unpacking system receives the tray crates through two feeding belts and inserts the trays into two conveyor belts in the packaging line.

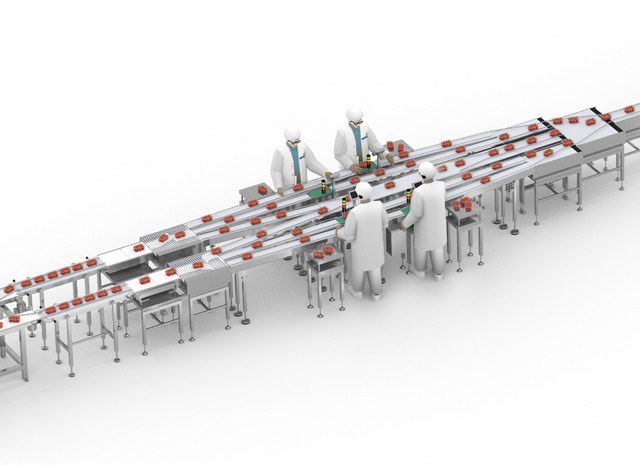

The weighing control area weighs each tray individually to distribute the trays according to their weight.

A group of operators is responsible for reducing and or increasing the content of each tray so that all trays that leave the weighing control area are with the weight adjusted to the established range.

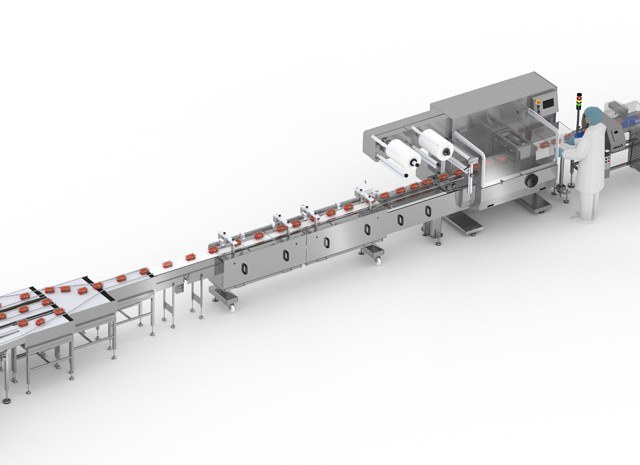

The flow pack wrapper performs the primary packaging of each tray of strawberries. To do this, an automatic feeder is responsible for positioning and obtaining the exact separation between trays so that the flow of the process is optimal.

The metal detection system inspects each package searching for metal contaminants just after the wrapper. In the event that it does not meet the requirements, the tray is rejected preventing it from following the course of the process.

The case packing system receives the pre-formed carton boxes and is in charge of automatically casing flow wrapped trays.

The carton box is open but with the characteristic that has a top fold that allows the stacking of boxes. That is why the boxer has to be specific for this type of box and take advantage of all available space.