Complete solution for frozen chicken cut-ups packaging in vertical (vffs)

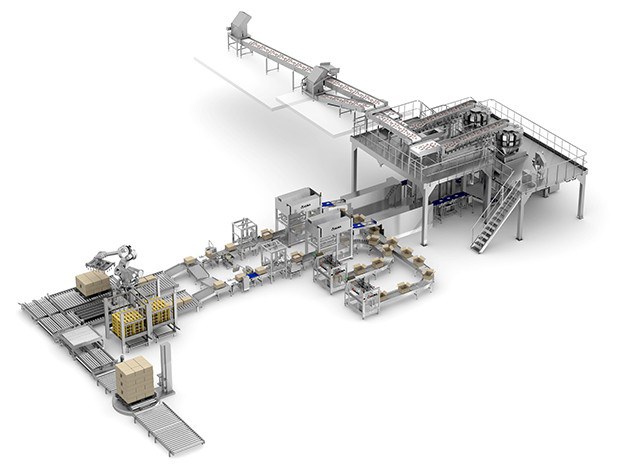

Complete solution for frozen chicken cut-ups packaging in vertical (vffs). The system is based in two packaging lines with automatic end of line for carton boxes and palletizing.

The product is received at the exit of the freezing tunnel (2 freezing tunnels) and transported by belts to the dosing system and two multi-head weighers supply automatically the product in the required doses for each package format.

The two VTC 840 vertical high-performance packaging machines (vffs) bag the frozen chicken cut-ups at a rate of up to 70 bags/minute. The VTC 840 features several innovations and advanced technology solutions.

- Tight-bag (TM): system that allows you to make non-perforated containers with a controlled air level inside the bag, for further optimization during packing.

- Sealflex (TM): Transverse sealing technology for LDPE film and laminated film that allows high production and sealing reliability with minimal maintenance. Alternative system to traditional impulse sealing.

- Automatic reel change: Double reel holder system, which allows automatic reel changes to be made, improving line efficiency and optimizing stop management.

Inspection systems are based on weighing control and detection of metallic contaminants.

The installation has two lines made up of box formers, drop-down cell that fill the boxes with the chicken cut-ups bags and automatic box sealer by means of adhesive tape.

Finally, the anthropomorphic robot is responsible for palletizing the boxes on pallets that are wrapped with shrink film and are ready for shipment.