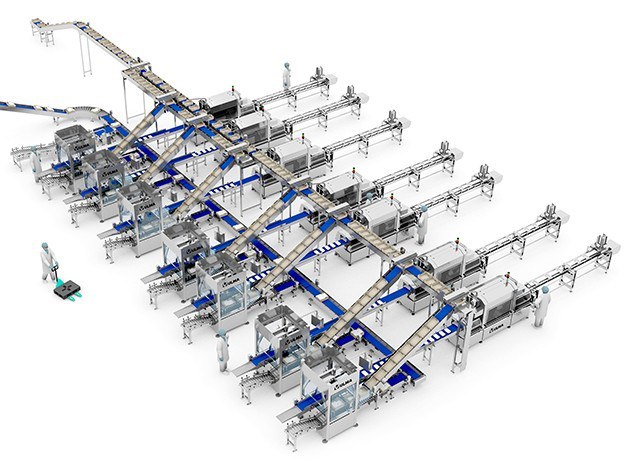

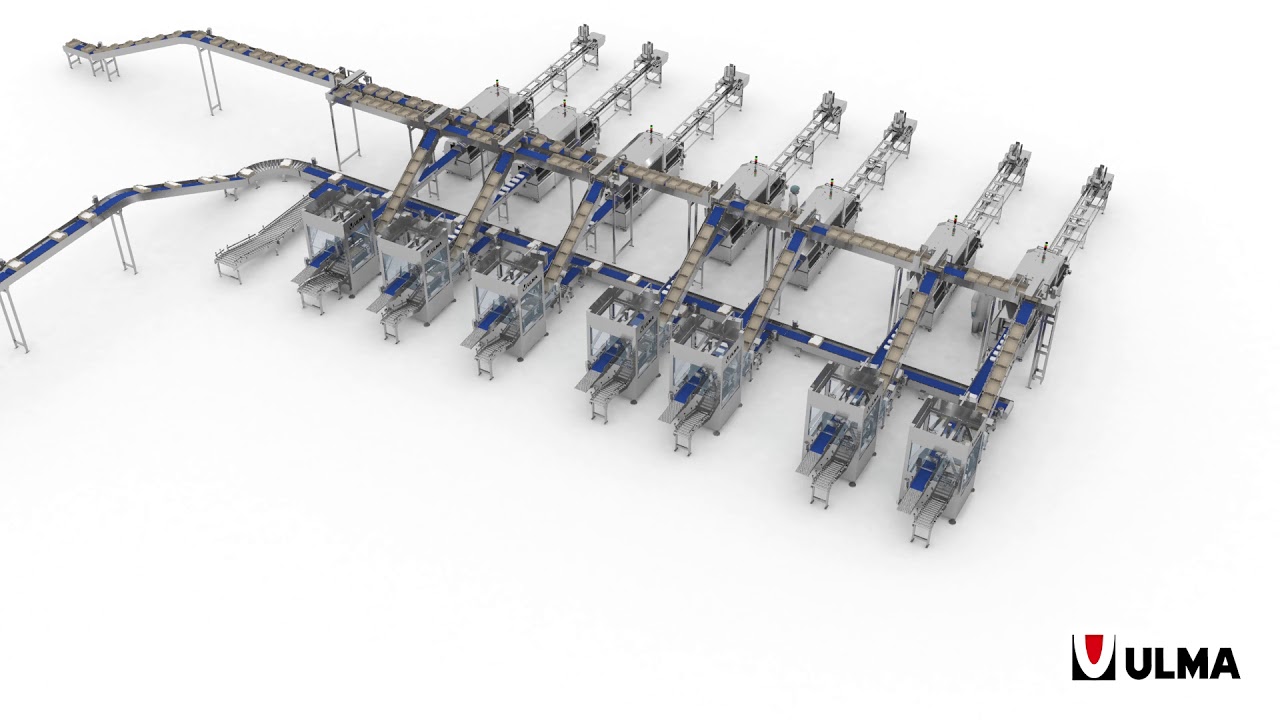

Complete solution for chicken cut-ups packaging in traysealing

The complete automation solution of the packaging plant includes seven packing lines for chicken cut-ups.

Each packaging line includes an automatic tray denester device that feeds the infeed conveyor of the traysealer.

Each of the seven automatic traysealers are TSA models that are highly equipped for the hygienic conditions that require fresh product packaging plants. The packaging of the different chicken cut-ups is done in trays that are hermetically sealed in modified atmosphere (MAP).

The carton boxes in which the traysealed packages are fitted come in conveyor belts and are distributed automatically to each of the lines through feed ramps.

Each of the seven lines are equipped with robotized case packing cells that are capable of forming the mosaic of trays required by the box. They are supplied with the empty boxes that arrive through the system of transport and distribution.

At the exit, the workers collect the carton boxes with the packages to be stacked and to form the corresponding pallets.