Complete solution for chicken breasts packaging in traysealing

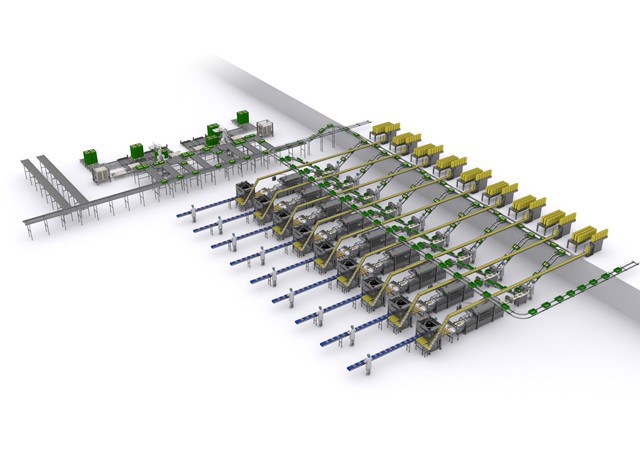

Complete solution for the packaging in traysealing of chicken breasts. The plant has nine traysealing lines and two palletizing cells.

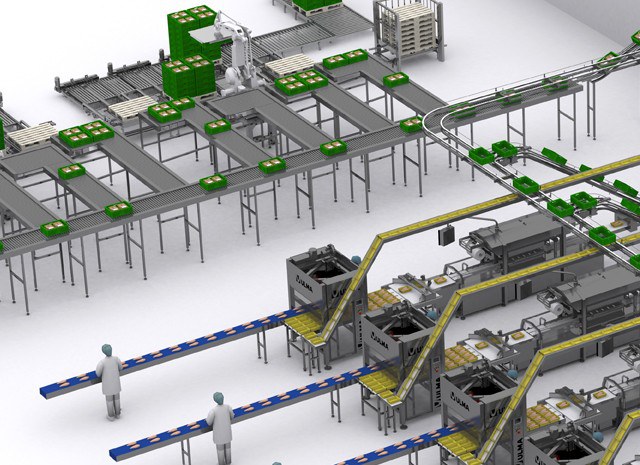

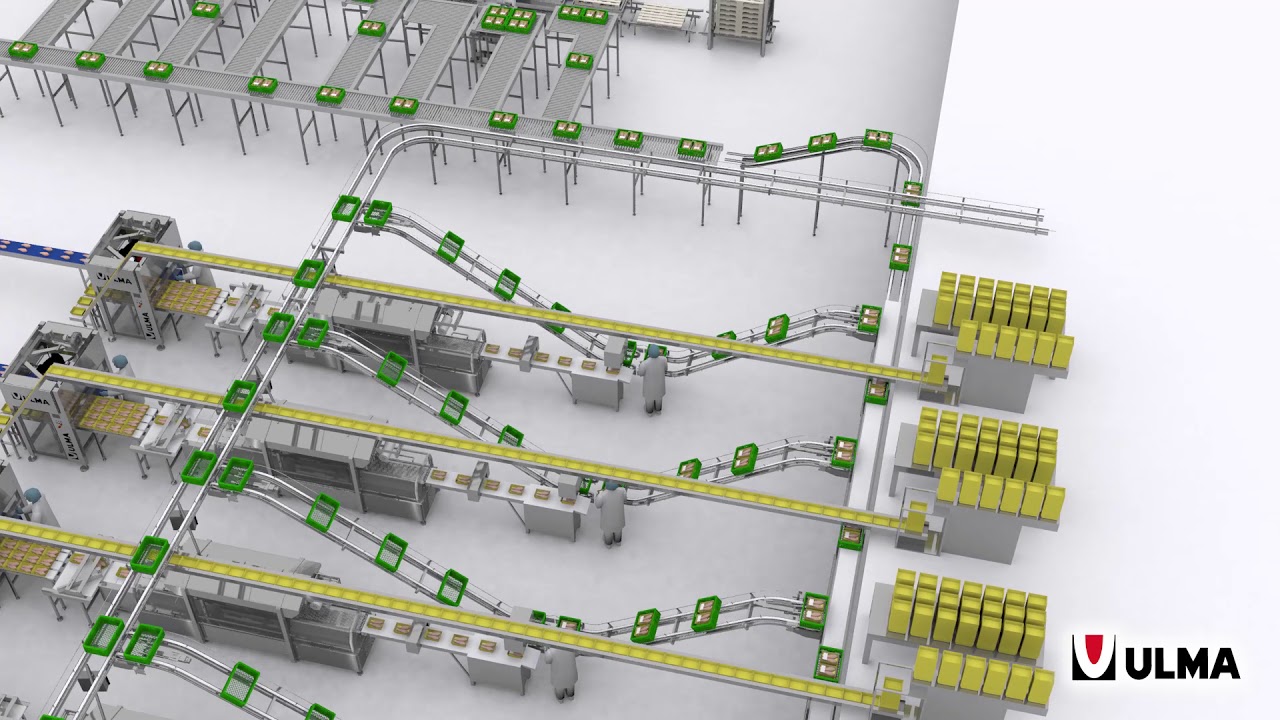

Both the distribution and the transport of trays and plastic crates are fully automated. The facility has warehouses of trays that are conveyed to the packaging lines. The plastic crates are also distributed to each line.

The loading of chicken breasts into the trays is done in an automatically by robots.

The nine traysealers are arranged in the nine lines which seal in modified atmosphere (MAP) the trays with the product previously loaded by the loading cell.

The inspection system is based in a metal detector that rejects trays that do not meet the requirements. Subsequently, they are labeled to move to the next phase which is the manual case packing.

An operator is responsible for each line of manually case packing the trays with product into the plastic crates received through the distribution ramps. Afterwards, all the boxes pass to the two palletizing cells that, by means of anthropomorphic robots, carry out the pallets automatically.