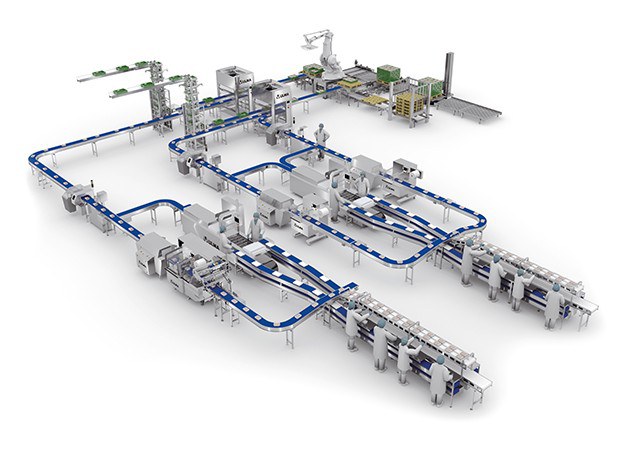

Complete solution for chicken breasts packaging

Complete solution for the packaging of chicken breasts in several technologies: on preformed trays packaged in flow pack wrappers with shrink barrier film and vacuum packaging with thermoforming machines.

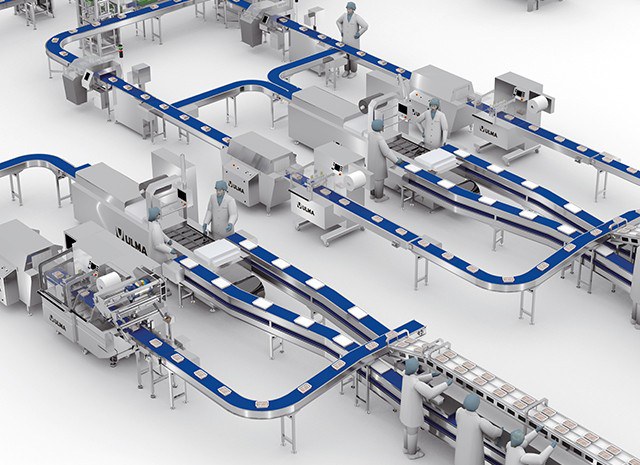

Operators have preparation tables to manually load the chicken breasts into the trays that are then directed to the flow pack packaging machines.

When the product is packaged in thermoforming, the product reaches directly to the operators who are positioned in the loading area of the thermoformer.

The packaging in flow pack wrappers is made with the product on a tray and wrapped in a modified atmosphere (MAP) with shrink film. Once the tray of the flow pack wrapper comes out, it goes through a hot air tunnel that shrinks the film around the tray giving it an excellent finish and shelf life.

When the packaging is in vacuum, the packaging is made in the thermoformer using a flexible film.

For both the product packaged in flow pack wrappers and the packaging in thermoforming, an inspection is carried out by means of metal detectors that are located at the exit of the packaging processes.

The packaged product is automatically fitted in plastic crates that come from descenders. This case packing process is carried out by flexible robotic cells capable of forming different mosaics depending on the crate and the packaged product.

Finally, all the plastic crates are directed to the palletizing area in which an anthropomorphic robot makes the stacking of crates over the pallets that once finished, are bundled with film for storage and transport.