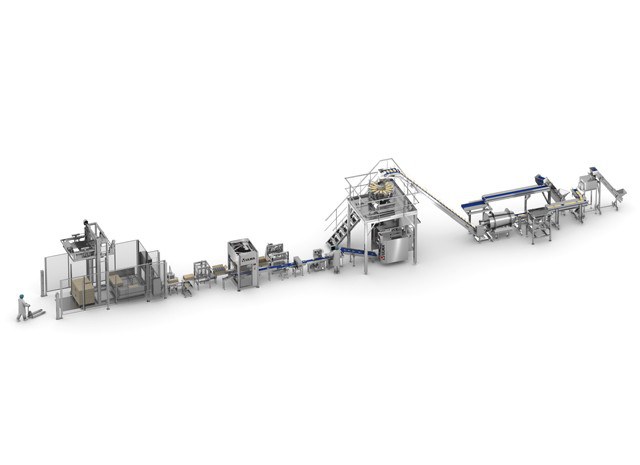

Complete solution for packaging of shredded cheese with carton boxes

Complete solution for packing grated cheese with automatic vertical bagger

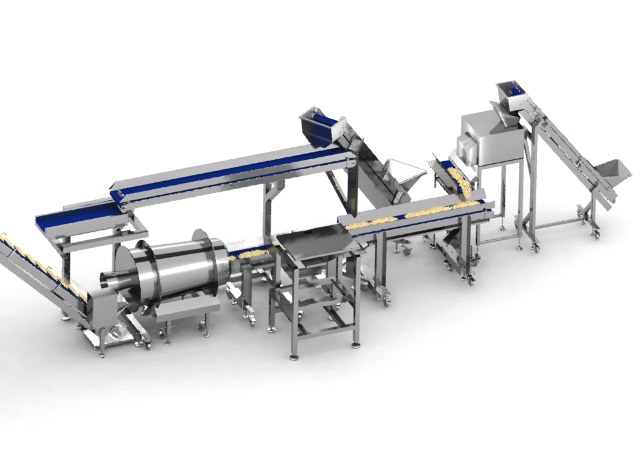

The packaging line begins with a cheese grater, the result of which is picked up by a belt that automatically reads the flow of received cheese, adding anti-caking (usually potato starch) in the correct proportion with respect to the reading of the received cheese flow.

Subsequently, all the cheese is transported to the tumbler, which homogenizes the mixture so that the product will not become compacted once packaged.

The product rises to the multi-head combination weigher that makes the necessary doses for each bag, transferring the product to the vertical packaging machine.

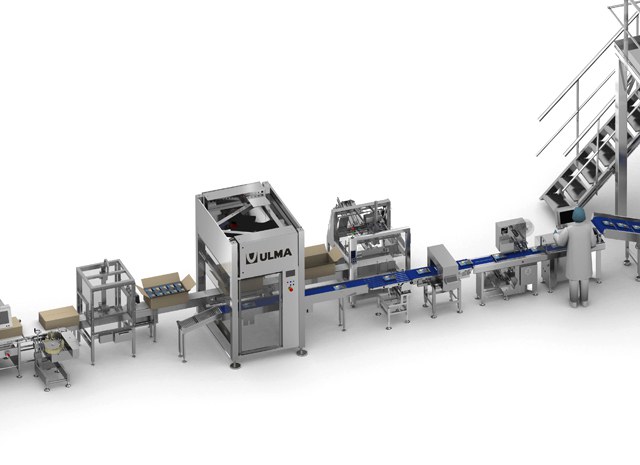

Both the multihead and the vertical packaging machine are flexible and designed to work with different bag formats. ULMA has different packaging models designed for the dairy sector, opting for the best model in each case, depending on the characteristics of the application in factors such as speed, dose and reclosable solutions.

The line has a metal detector with rejection and automatic labeling for packaging.

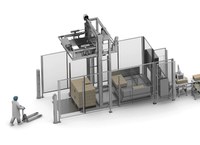

The robotic case packing cell is made up of an automatic carton case erector, a case packer robot and an automatic box closer.

The case erector produces cardboard boxes that are sent by means of transport elements to the case packing cell. At this point, a robot handles the incoming products and puts them in the empty box. For this, the robot has a gripper that, in addition to putting the product in the box, ensures that the product is left correctly and the box comes out complete. At the end of it, the box is closed in the closer system.

The three elements of the robotic cell are flexible, quick to configure and easy to maintain. This allows the cell to be adapted to different customer production formats or to configure new formats if necessary.

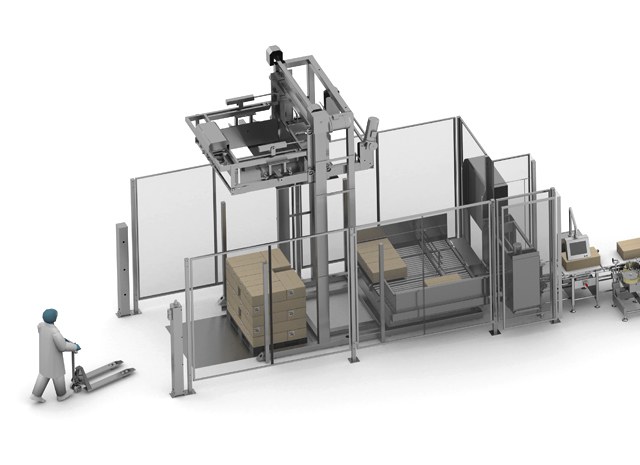

Finally, by means of a mechanical palletizing system, the pallets of boxes with the packages are made.