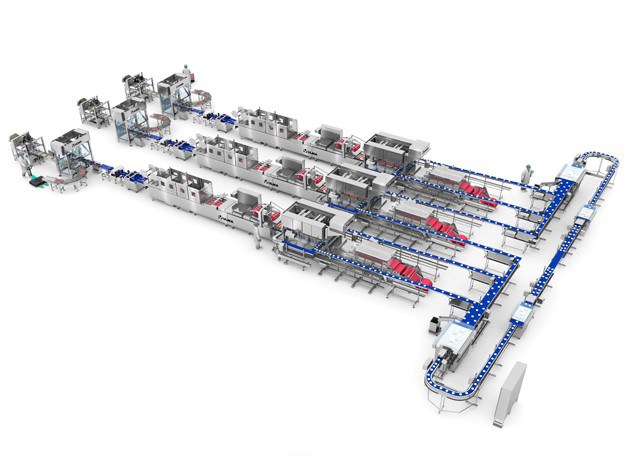

Complete solution for packaging of fresh cheese

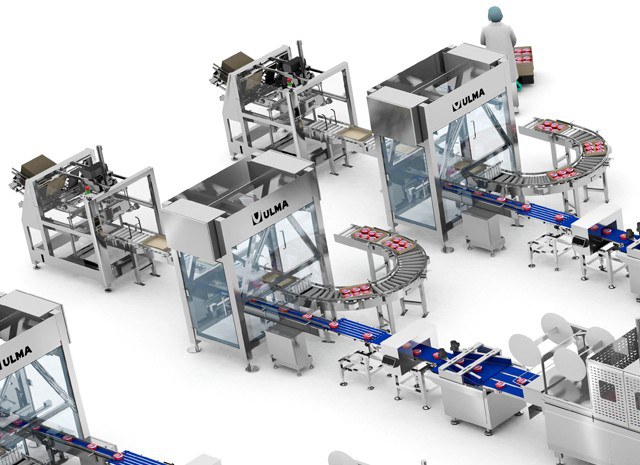

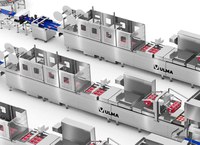

Fully automated complete solution for fresh cheese consisting of three packaging lines with thermoformers.

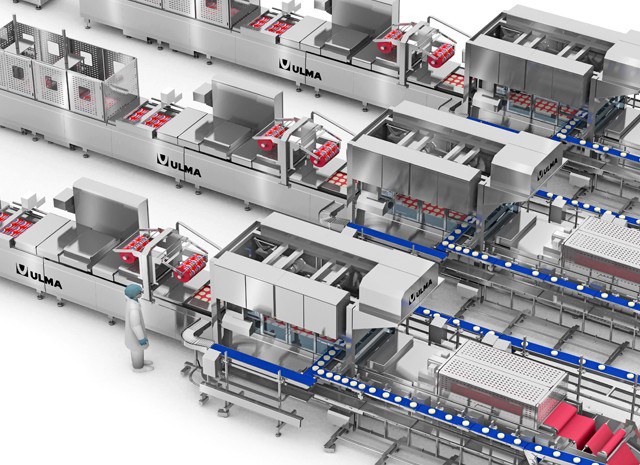

The first phase of the installation is responsible for receiving and transporting the fresh cheese to the thermoformers.

By means of a conveyor system specially adapted for fresh product that facilitate the cleaning tasks, the product flow is divied into two areas that distribute the product in a balanced way towards the thermoformers.

The robotic loading cells receive the product from both sides through the infeed belts and product is loaded automatically into the preformed cavities made by the thermoformer.

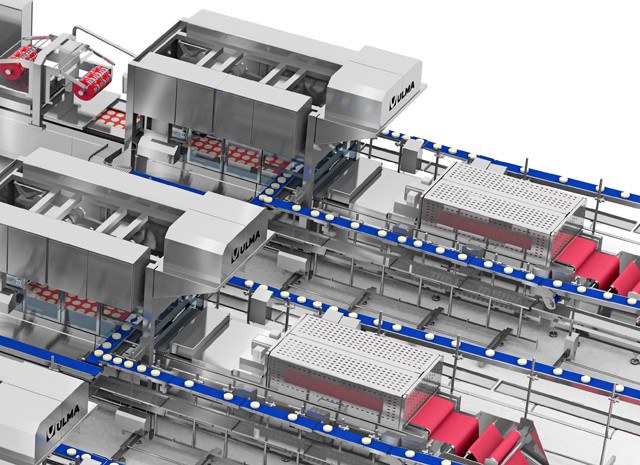

The three thermoformers that equip the complete installation perform the lower cavity of the package with rigid plastic film and then seal the lid with the upper film.

They are equipped with an automatic reel change of upper film and a inline coding system.

Before ejecting the containers, they are die-cut with a customized shape specially adapted to the client' s design.

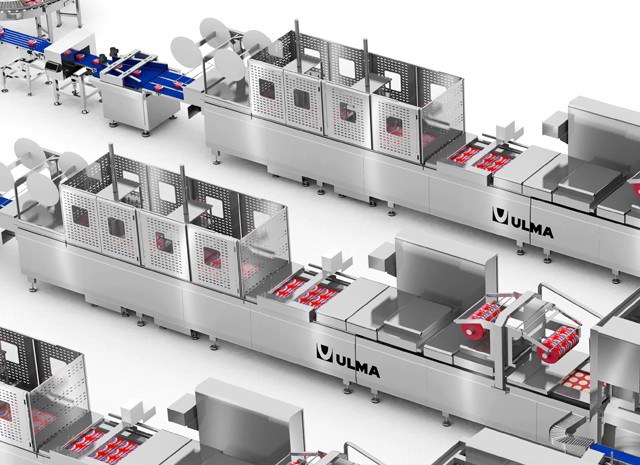

The aligner is place just after the thermoforming machine and converts the three package rows into a single one so that they can later be inspected by the metal detector arranged just before the case packer.

Each of the three lines has a case erector that forms the carton boxes with the stacked the carton sheets. The robotized case packing cell is responsible for introducing the thermoformed packages in the boxes, arranging them according to the required mosaic for the packages.

The stacking of boxes and transport of pallets is manual and it is the operators who are responsible for these tasks.