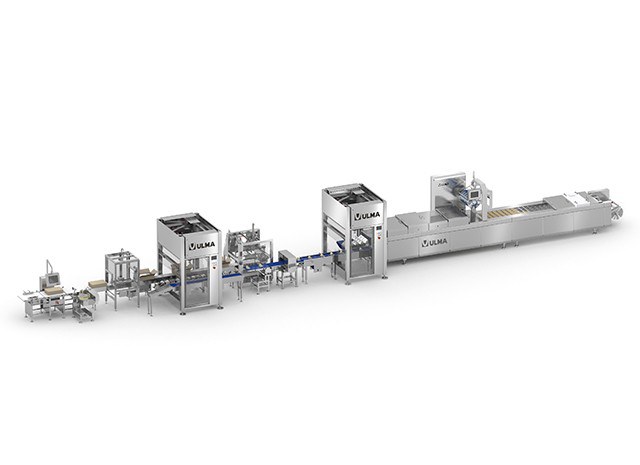

Complete solution for packaging of cheese wedges in thermoforming

Complete line of fully automated packaging for cheese wedges in flexible thermoforming.

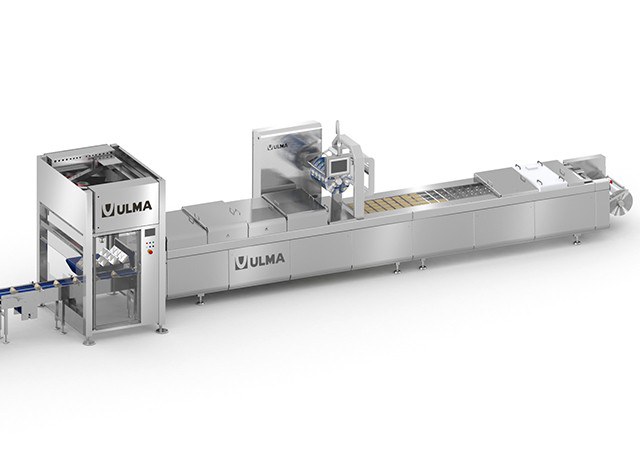

The first phase of the line is the vacuum packaging of cheese wedges in thermoformed packages and sealed in the same machine. With printed cover film, the thermoformer performs packages in rows of three.

The packaged product leaves the thermoformer in rows of three and by means of a robot, one row is collected for each cycle, aligning them in a single row and rotating them before depositing them on the following belt.

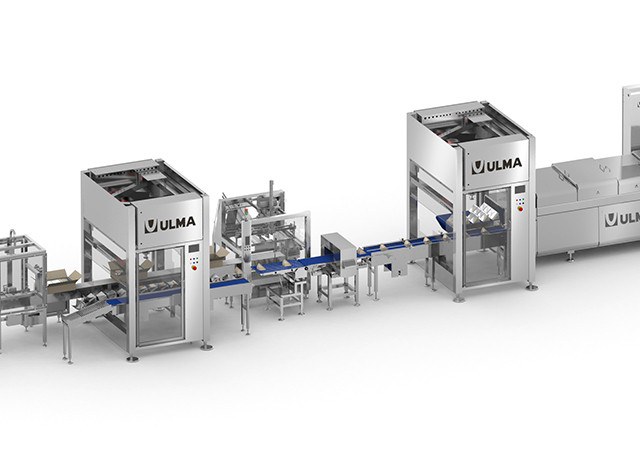

An inline integrated metal detector performs the inspection of each package just before the case packing process in order to reject those that may contain traces of metallic origin that contaminate the product.

The case packing cell receives the empty carton boxes from a case erector that performs boxes from carton sheets.

The robot is responsible for making the mosaic of packages in the box alternating the orientation of the wedges of cheese so that the use of the volume of the box is optimal.

Finally, an automatic box closing system seals the boxes so that later a labeling machine can put the identification on it.