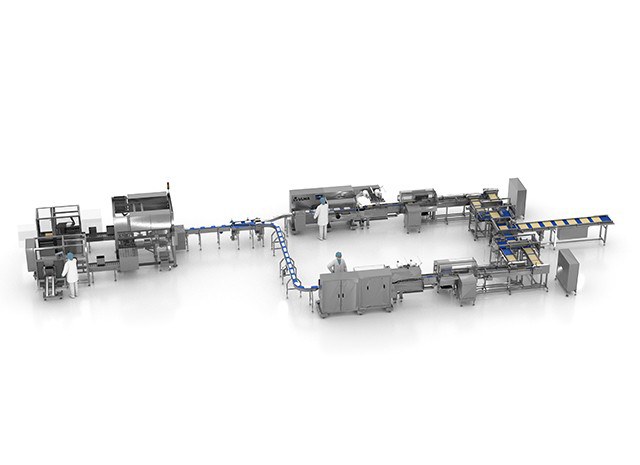

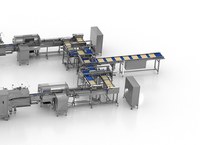

Wafers - Full line for automated packaging and case packing

Full line for the primary packaging of wafers and automatic 2-in-1 packing (top loading and side loading).

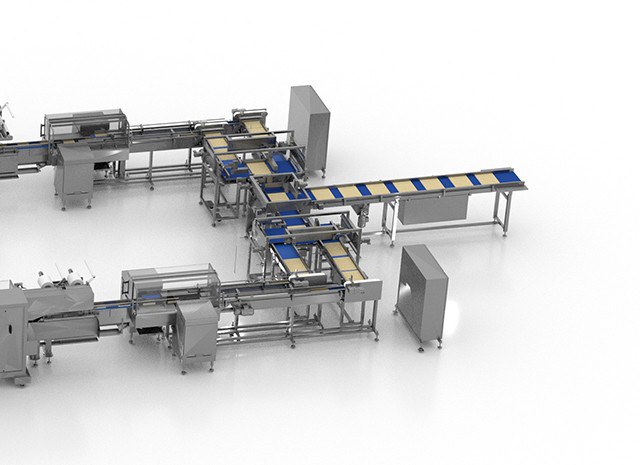

The system is fed the processed blocks of wafers. The system can distribute the product to one or two machines, depending on the packaging format. Furthermore, in the event of a machine shutdown, it is equipped to divert the product to the machine that is not in operation.

A servo-controlled pusher system is used to perform the transfer.

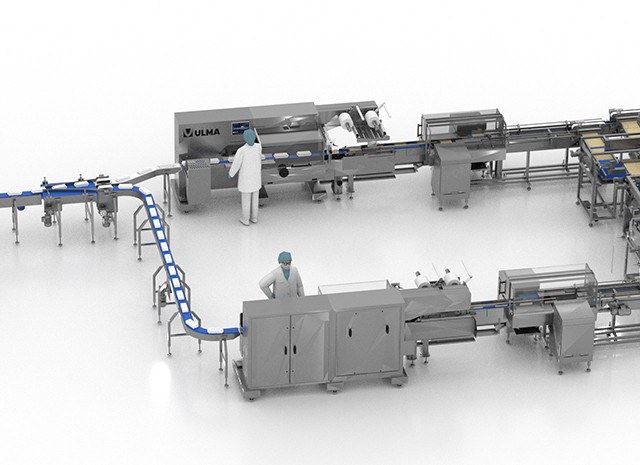

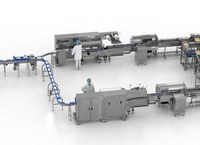

The product is collected on one side of the primary packaging machine, where a transfer system introduces the product onto the Atlanta HT horizontal wrapper' s conveyor belt.

This packing cell makes it possible to perform TOP LOAD and SIDE LOAD packing in a single cell. It has a delta robot and two packing stations for this purpose. One of the two packing stations will be used, depending on the packing method.

The cell collects the products from two wrappers, groups them together and then packs them into a cardboard box. TOP LOAD packing is performed directly in the box, while during SIDE LOADING, the box is prepared beforehand and then loaded.

It is a single-block, compact and flexible cell for solutions that require both types of packing.