Soft bread & buns - Automated packaging and case packing

Automated packaging and case packing for soft bread & buns

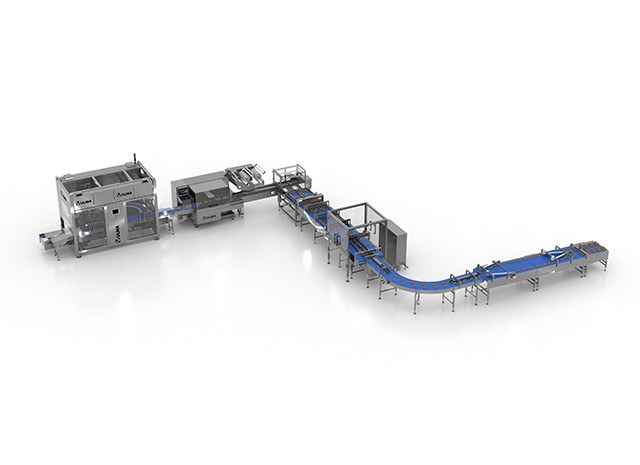

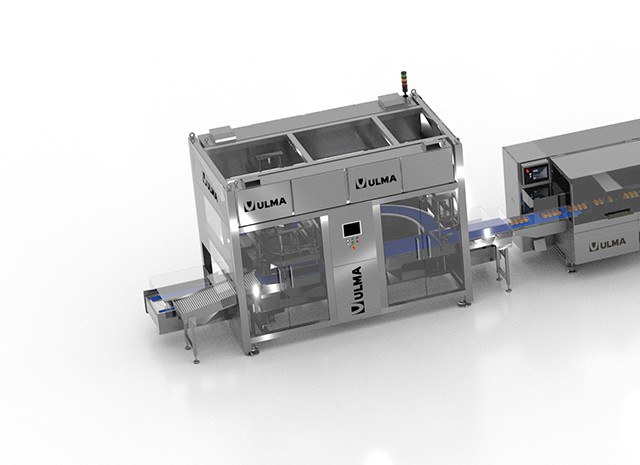

The product is fed from the spiral cooler. Using a chicane system, the product is aligned to form two lines of products. A double multiplier distributes the product to the grouping module' s various channels.

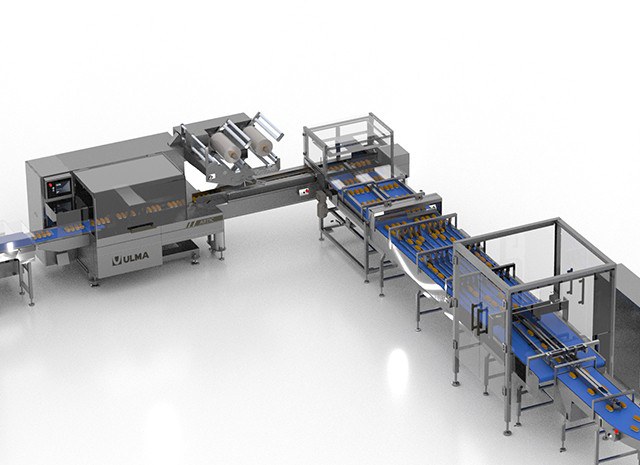

The bundle of products is transferred to the machine' s feeder conveyor, which transports the product to the Artic horizontal wrapper.

The wrapper is equipped to work with MAP, with aroma dispensing.

Hot dog bag packing cells are devices that have a servo-driven handler to obtain the required stacking pattern and pack the products in the boxes. They are flexible and configurable systems with intuitive operation. Operators can change existing patterns or programme multiple new box patterns, with the ability to view the configuration on the HMI. It is also a single-block cell, which reduces the unit' s start-up times and, depending on the required output speed, there can be a single or double handler to achieve the most demanding output speeds.