Snack bars - Automated packaging and case packing

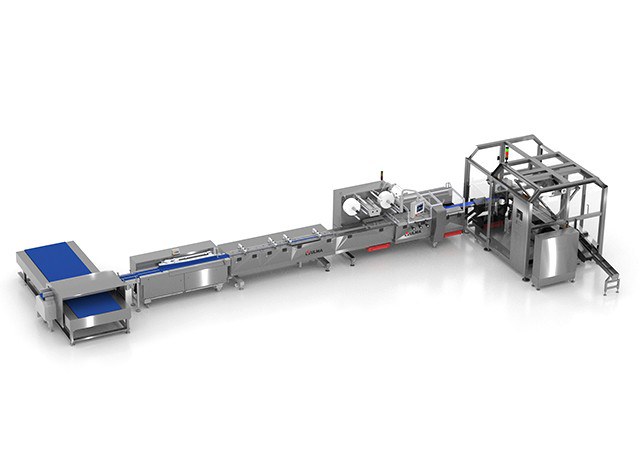

There are three different main components to this line for bars: (1) Bar row distributor, (2) FR 500 horizontal flow pack wrapper using material that is 100% paper and (3) automatic top loader boxing cell

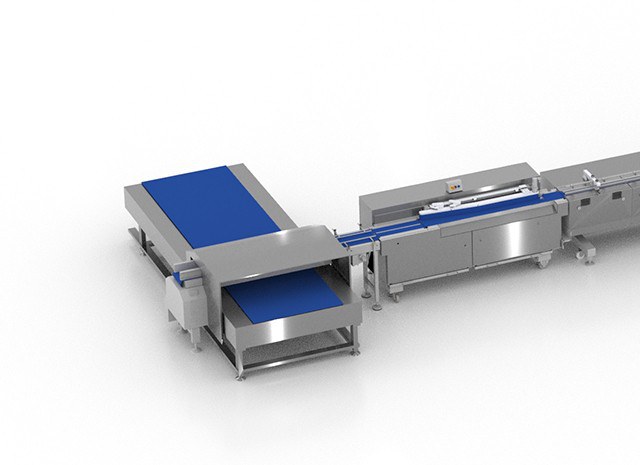

A product distributor that ensures an efficient, continuous flow towards the horizontal wrapper.

In a typical configuration for this type of line, the row distributor can be composed of several modules.

To improve its OEE, the line has a buffer conveyor, where the rows are collected when there is an unscheduled system stoppage. Increasing the speed of each branch when the machine error is resolved and operation is resumed, the system distributes the rows that have accumulated in the buffer by combining them with the incoming flow without having to stop the upstream process.

The design of our line' s distributor and primary packaging branch allows each component to be removed to facilitate cleaning and maintenance operations. Each component has been designed to enable their assembly when cleaning operations have been completed, thus preventing any errors during this process.

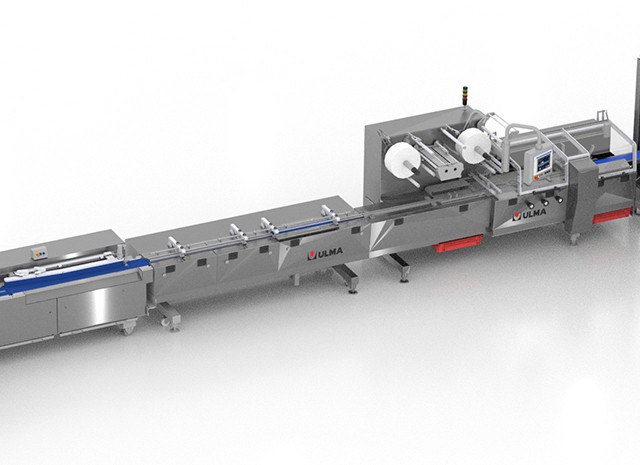

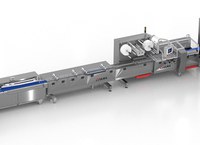

After transferring the product to the primary packaging branch, the products are repositioned to place them end-to-end. Quality control is performed in this position and any products that are out of tolerance are rejected before they reach the multi-conveyor feeder.

Depending on the application, the multi-conveyor feeder is configured to operate with or without contact between products.

When the product is fed into the FR500 horizontal wrapper, which can reach up to 1000 packages/minute, the product is packaged at high speed using material that is 100% paper, thanks to the special design of the film former.

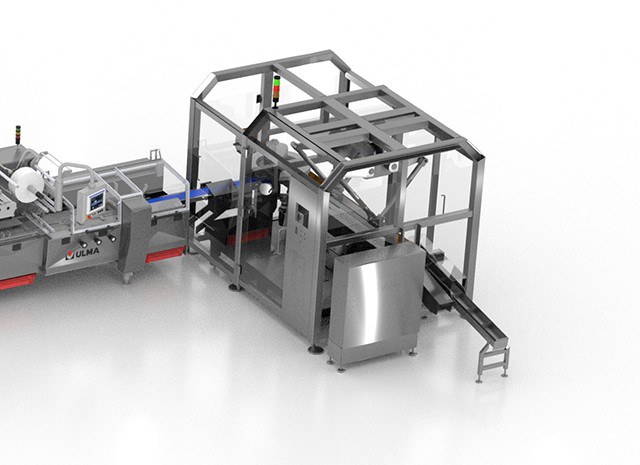

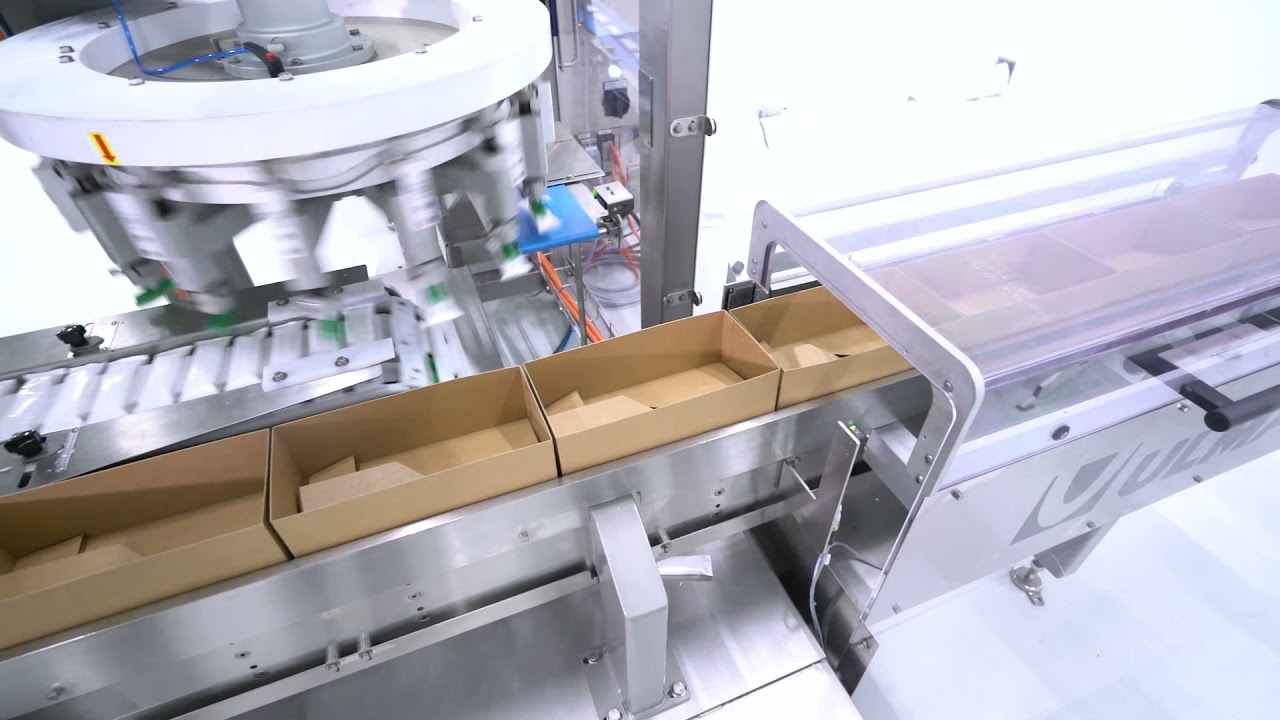

The bar top loader cell is a device that inserts groups of bars into cardboard cartons. Bars and automatically-formed cardboard cartons are fed to the cell, which uses a delta robot to collect and load them. The robot loads groups of bars into several cartons simultaneously and, when they are full, it sends them to the automatic carton sealing machine.

This is a high-speed, compact and single-block loading cell. This means that the system takes less time to start up and it occupies minimal space in the customer' s facilities.