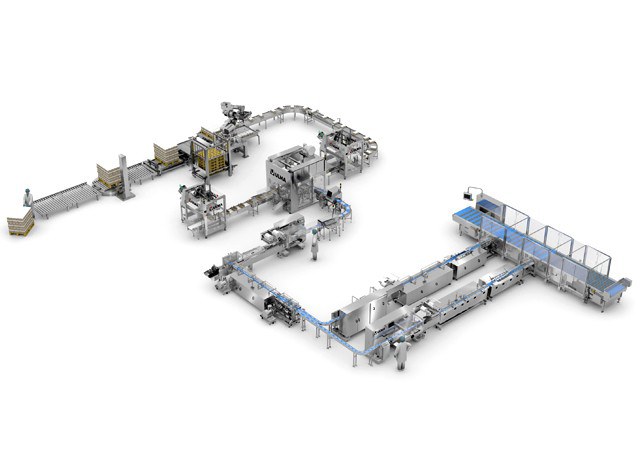

Complete solution for sweet baked goods packaging

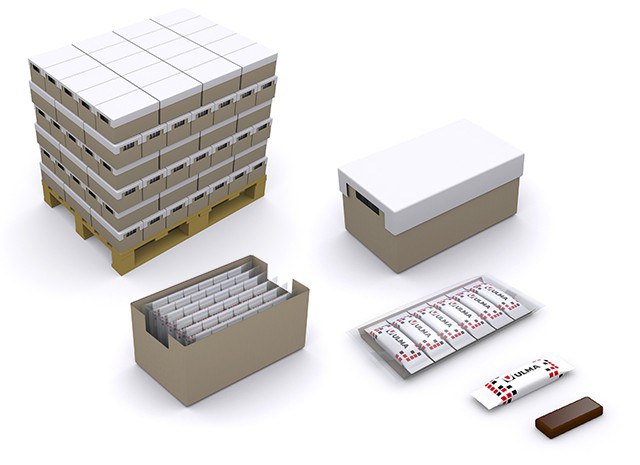

Packaging and case packing line for sweet baked goods that includes unitary and multipack packaging, as well as the case packing in an display box.

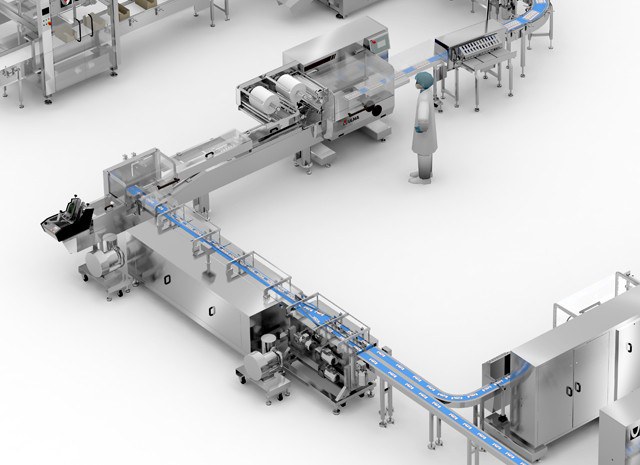

The row distributor system feeds the two primary flow wrapping lines, removing rows of product from the main product belt.

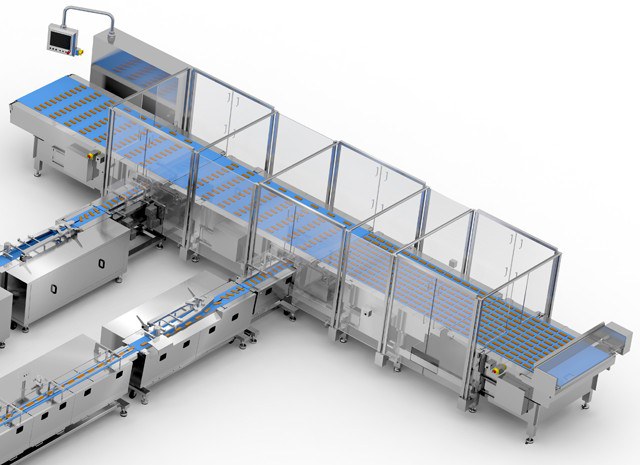

The multibel feeding system prior to primary packaging performs the alignment of products and achieves the exact separation to maximize the flow and production.

Two high speed flow pack wrappers machines perform the primary packaging of sweet baked goods.

By means of a system that carries out the grouping of unitary packages, a third flow pack wrapper performs the secondary packaging.

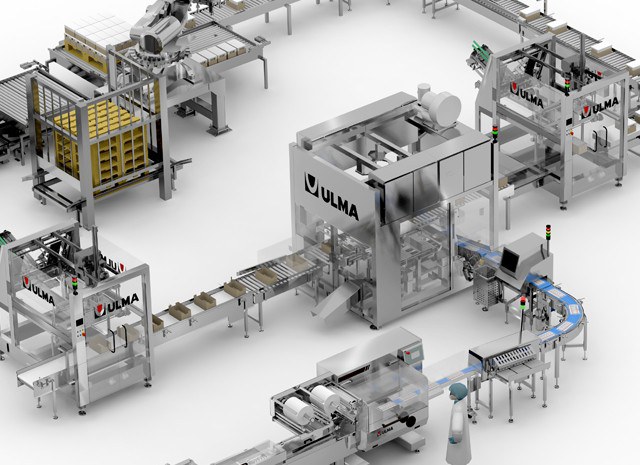

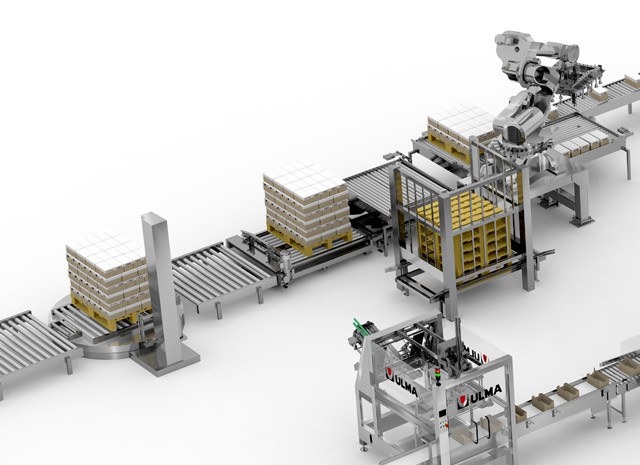

A case erector performs the base of the carton box so that in the case packer cell, the robot inserts the secondary package in the box. Later, another case erector performs and puts the hood.

The hood is the display box that will then be shown in shelves with the multipacks.

Robotic palletizing is responsible for the realization of pallets of boxes that are finally wrapped with stretch plastic film.