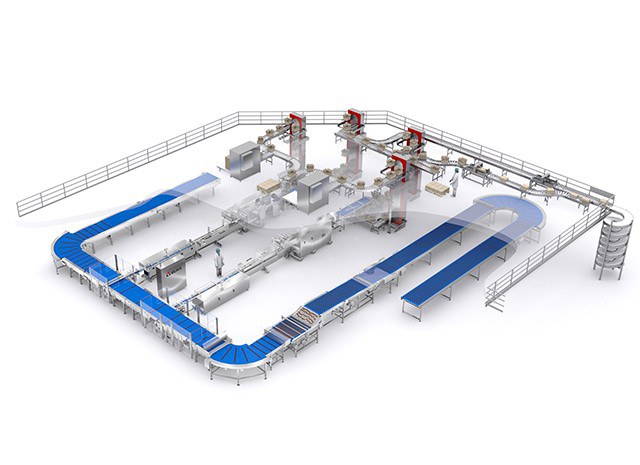

Complete solution for biscuit packaging and boxing

Turnkey automated installation consisting on product manipulation by means of rows distribution system, two primary flow wrappers and bulk case loading.

The installation begins with the transport of biscuits from the oven and alignment in regular rows.

The row distribution system feeds the two unitary packaging lines in flow pack and has a product buffer that functions as a product stocking to feed the row distribution system.

The biscuits are received through the row distribution system, are first stacked on a pile of two and by means of a multibelt system, are prepared with the required separation for the flow pack wrappers.

Once wrapped in flow pack, they are stored in the carton boxes that are received through the descenders from the upper floor.

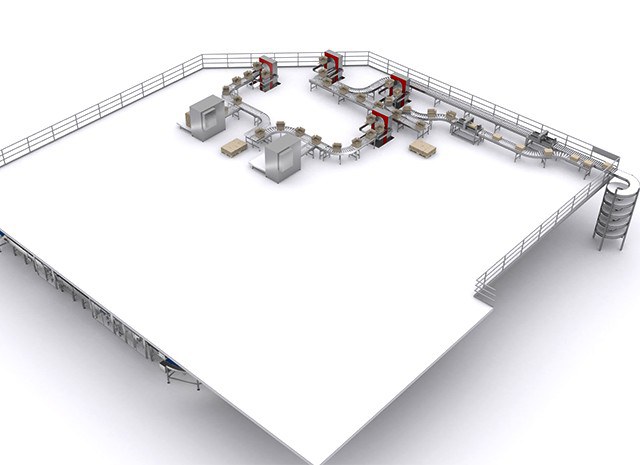

In the upper floor, two box case erectors are used, forming them from sheets and then feeding the transport system and box descenders that supply the lower plant where the packaging machines are located.

The installation has lifts and descenders of boxes to descend empty boxes and upload the full ones.

The boxes are bulk loaded and once filled, go up through the lift to the upper floor to be automatically closed and delivered through conveyor belts and a downward spiral to the finished product area.