Biscuits - Primary and multipack sustainable packaging

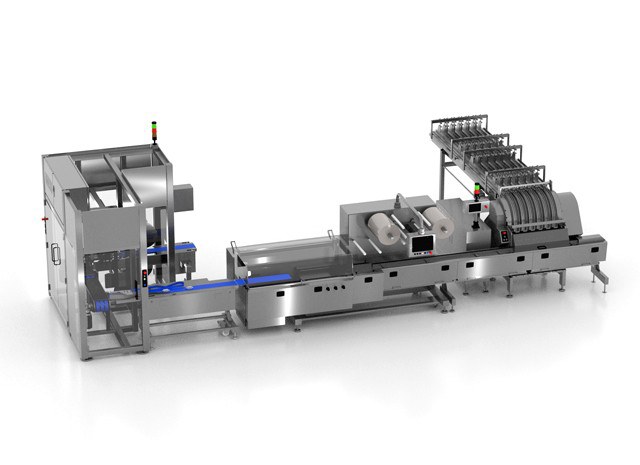

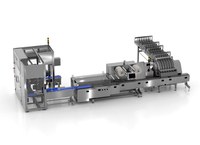

This packaging line has been designed for totally sustainable packaging. The primary packaging and the multipack are made exclusively with 100% recyclable paper. In addition, the multipack is made with two adhesive paper labels that replace the usual secondary packaging, reducing the amount of packaging material used.

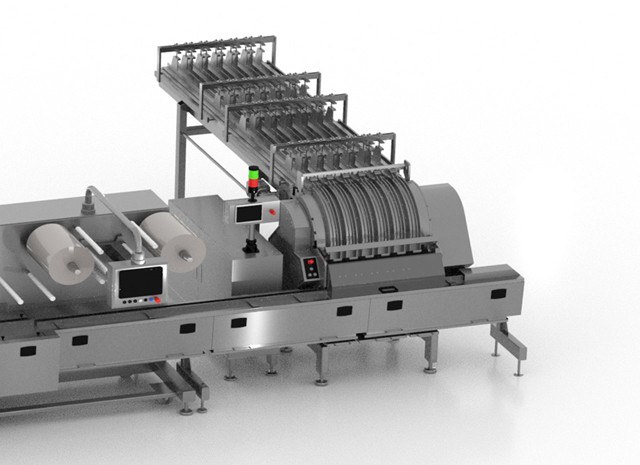

The pile loader receives the biscuits already stacked from the process, in 6 channels. In this case, piles of 4 biscuits are formed, although the system’s flexibility makes it easy to program it for piles of up to 10 biscuits.

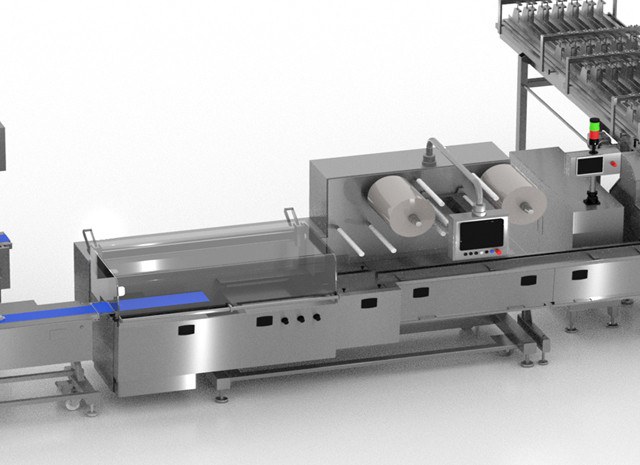

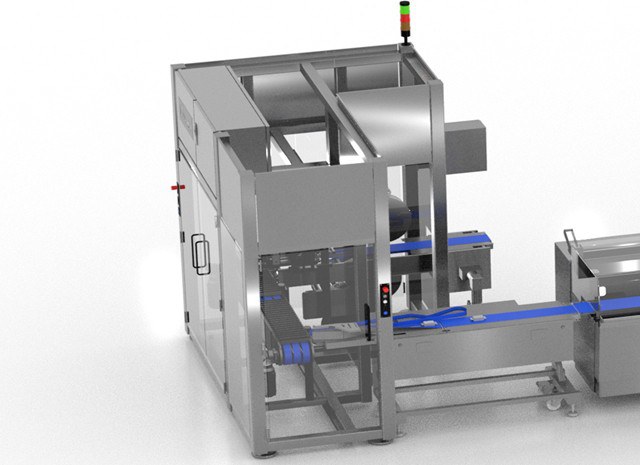

The piles are transferred precisely and carefully to the infeed conveyor of the FR 400 wrapper, synchronizing the speed.

The HMI control of the wrapper allows you to intuitively manage all of the production parameters and allowing to be controlled remotely.

A sensor checks the piles that are fed to the Flow Pack, rejecting them if they do not meet the product parameters defined as valid.

The FR 400 model allows production of up to 70 linear metres of film per minute.

The biscuits are handled carefully to minimise damage throughout the process.

The packaging is a fully recyclable film made of 100% paper.

After completing the primary packaging, the empty or wrong packages are rejected from the production line.

The packages are stood up before being transferred to the race track, where they are grouped in 5 units. These units are joined by applying two adhesive labels, also made of paper, one on each side of the group, forming the sustainable multipack.

The labels have been designed with pre-cuts to make it easier to separate the packages and consume them individually.