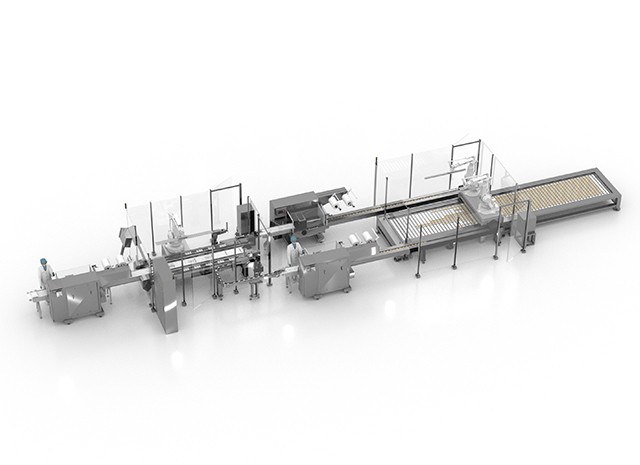

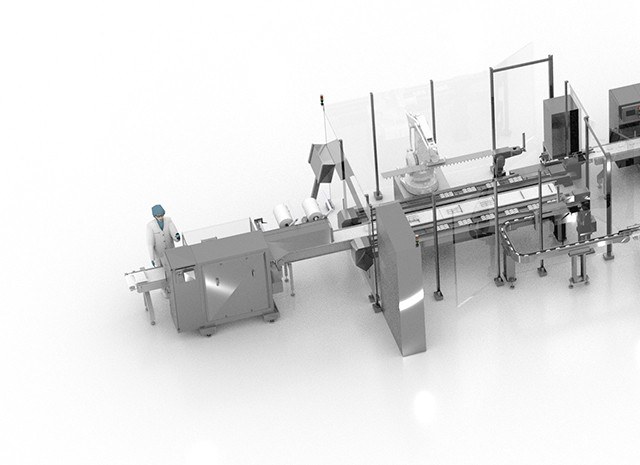

Baked goods - Automated line for primary and multipack packaging

There are four different main components to this full line for commercially baked goods: (1) Flow pack wrapper automatic product loading cell, (2) flow pack primary packaging system, (3) automatic loading cell for multipacks and (4) flow pack multipack packaging system

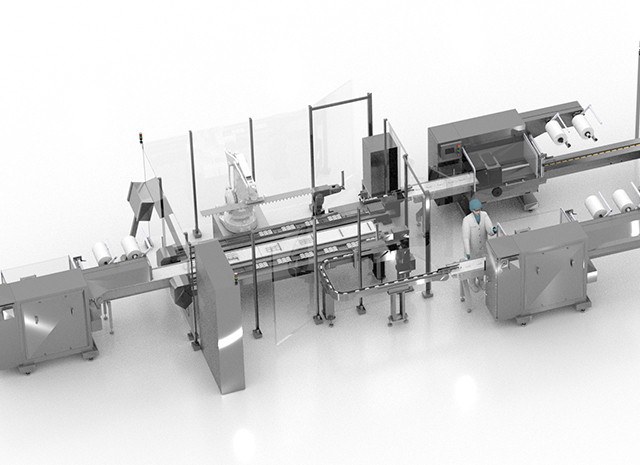

The single flow pack loading cell is composed of two anthropomorphic robots which collect the product from the customer' s oven and load it onto the flow pack conveyor.

The robots each have their own section of the customer' s oven and they are synchronised with it to perform phased unloading. After the products have been collected, they are each loaded it into their respective flow pack wrappers. The robots are also synchronised with the wrappers to ensure that loading is performed correctly between paddles, without damaging the fresh product.

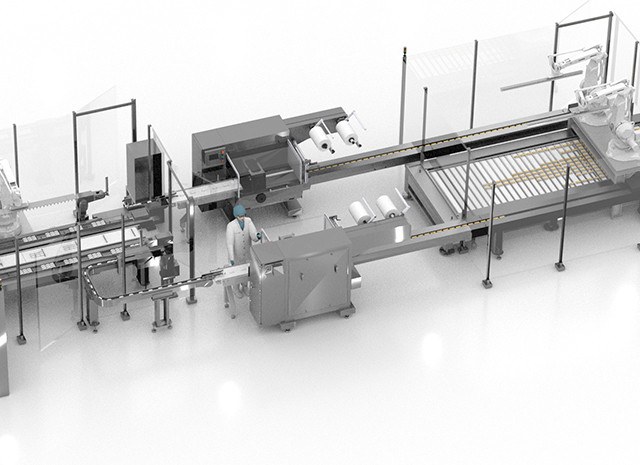

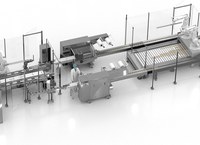

The product is fed to two Atlanta HT horizontal wrapping machines by two robots. A special interface facilitates the loading of the product onto the machine' s belt.

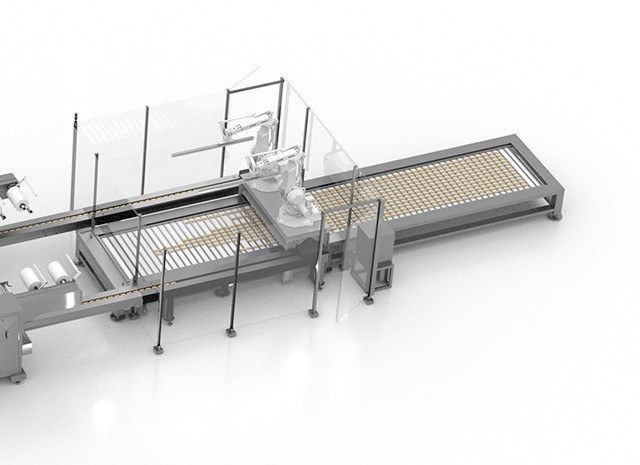

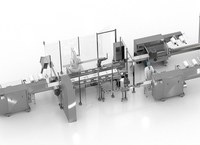

The multipack flow pack loading cell is composed of two product grouping anthropomorphic robots and one flow pack conveyor loading anthropomorphic robot.

The packaged products are received from two single flow pack wrappers and there is a robot at each of their outlets that puts them into groups. Each robot gathers these groups onto a paddle conveyor until it has a specific number of groups. When that number is reached, the loading robot collects all of the groups at once and loads them onto the multipack flow pack wrapper.

The operation of all components of this cell is integrated with the single flow pack wrappers so that all of the systems work as one, ensuring the simple and intuitive operation of the whole line.

An Atlanta HT horizontal machine is fed the product by a robot. To facilitate the loading of the product, the machine works intermittently.